Otu ụlọ nyocha ụlọ nyocha na-eji skru na-atụgharị agbaze, gwakọta ma na-akpụzi polymer n'ime gbọmgbọm ọkụ. Ndị nchọpụta na-adabere naventilashị otu ịghasa extruder, otu ịghasa igwe, naigwe granulator enweghị mmiriiji nweta ngwakọta kacha mma na nchekwa, nhazi dị irè. Nnyocha na-egosi naịghasa ọsọ na okpomọkụna-emetụta ogo ngwaahịa na nchekwa ozugbo.

Ihe ndị bụ isi nke Otu Screw Extruder

Ihe mkpuchi ahụ

Ihe ịghasabụ obi nke otu ịghasa extruder. Ọ na-atụgharị n'ime gbọmgbọm ahụ ma na-ebugharị polymer n'ihu. Ihe nkedo ahụ na-agbaze, na-agwakọta, ma na-ebugharị ihe ahụ n'ebe anwụ anwụ. Nhazi nke ịghasa, gụnyere dayameta, ogologo-na-dayameta ruru, na oke mkpakọ, na-emetụta ka polymer si agbaze na ngwakọta. Ihe nkedo a haziri nke ọma na-eme ka ọ̀tụ̀tụ̀ ịgbaze agbaze na ịrụ ọrụ nke ọma. Grooves na ịghasa ma ọ bụ gbọmgbọm nwere ike ịbawanye ọsọ ọsọ ma nyere aka ịchịkwa usoro ahụ. Ọsọ nke ịghasa na-agbanwekwa ọnụ ọgụgụ nke ngwakọta na okpomọkụ na-emepụta.

NDỤMỌDỤ: Ịgbanwe ọsọ nke ịghasa nwere ike inye aka ịchịkwa okpomọkụ gbazee na àgwà ngwaahịa.

The Barrel

gbọmgbọm ahụgbara gburugburu ịghasa ahụ ma jide polymer ka ọ na-agagharị. gbọmgbọm ahụ nwere mpaghara okpomọkụ dị iche iche. Enwere ike ịtọ mpaghara ọ bụla n'otu ọnọdụ okpomọkụ iji nyere aka gbazee polymer nke ọma. Dịka ọmụmaatụ, mpaghara mbụ nwere ike ịdị jụụ iji nyere aka ịkwaga polymer siri ike, ebe mpaghara ndị ọzọ na-ekpo ọkụ iji gbazee ihe. Njikwa okpomọkụ kwesịrị ekwesị na gbọmgbọm dị mkpa maka ịdị mma nke ọma na àgwà ngwaahịa.Thermocouples na-atụle okpomọkụ dị n'ime gbọmgbọmiji mee ka usoro ahụ kwụsie ike.

- Ntọala okpomọkụ Barrel na-adabere n'ụdị polymer na ịghasa nhazi.

- Ndị na-apụ apụ nke oge a na-enwekarị mpaghara okpomọkụ atọ ma ọ bụ karịa.

- Akụkụ nri kwesịrị ịdị ọkụ mana ọ bụghị oke ọkụ iji zere ịrapagidesi ike ihe.

Sistemụ kpo oku

Usoro ikpo ọkụ na-edobe gbọmgbọm ahụ na okpomọkụ kwesịrị ekwesị. A na-etinye ndị na-ekpo ọkụ n'akụkụ gbọmgbọm ma na-achịkwa ihe mmetụta. Usoro ahụ nwere ike ịhazigharị mpaghara ọ bụla iji kwekọọ na mkpa nke polymer. Ezigbo njikwa ikpo ọkụ na-enyere aka izere nsogbu dị ka ihe na-ere ọkụ ma ọ bụ agbaze na-enweghị isi. Usoro ikpo ọkụ na-arụ ọrụ na usoro nchịkwa iji mee ka usoro ahụ dị mma ma dị irè.

The Die

The anwụ na-akpụzi polymer gbazere ka ọ na-ahapụ otu ịghasa extruder. Ntupụta anwụ na-emetụta udi, elu na nha nke ngwaahịa ikpeazụ. Ịnwụ anwụ dị mma na-enye ihe dị nro, ọbụna na-asọba ma na-enyere aka mee ngwaahịa na akụkụ ziri ezi. Nwụrụ anwụ ga-ejikwa ọnọdụ okpomọkụ na nrụgide kwesịrị ekwesị iji zere ntụpọ. Mgbanwe na okpomọkụ anwụ ma ọ bụ eruba nwere ike ịgbanwe àgwà ngwaahịa.

- Ọsọ ọsọ n'ụdị na obere nrụgide nrụgide na ọpụpụ anwụ dị mkpa maka ịdị mma.

- Jiometry ọwa anwụ na nguzozi na-erugharị na-emetụta izi ezi nke udi ngwaahịa.

Sistemụ Njikwa

Usoro njikwa na-ejikwa otu ịghasa extruder arụ ọrụ. Ọ na-enyocha ọnọdụ okpomọkụ, nrụgide, ịghasa ọsọ na ọnụego nri. Ndị na-arụ ọrụ na-eji usoro njikwa iji tọọ ma mezie paramita usoro. Nleba anya nke oge na-enyere aka mee ka usoro ahụ kwụsie ike na nchekwa. Usoro nchịkwa nwekwara ike ịchekwa ntụziaka maka polymers dị iche iche, na-eme ka ọ dịkwuo mfe ịmegharị ọsọ ọsọ na-aga nke ọma.

Ụdị nke Single Screw Extruder maka ojiji ụlọ nyocha

Ntọala ụlọ nyocha chọrọ ụdị extruders dị iche iche iji gboo mkpa nyocha akọwapụtara. Ụdị ọ bụla na-enye atụmatụ pụrụ iche na uru maka nhazi polymer.

Otu screw Extruder ventilashị

Otu skru extruder ventilashị na-eji aabụọ-ogbo ịghasa imewe. Nke a imewe na-ebelata torque na horsepower mkpa ka ịnọgide na-enwe mmepụta na ịghasa ọsọ. Usoro ikuku na-ewepụ mmiri na gas sitere na polymer gbazee. Nzọụkwụ a dị mkpa maka nhazi plastik na-amịkọrọ mmiri. Iwepu ihe ndị a na-agbanwe agbanwe na-egbochi ntụpọ dị ka splay na akụrụngwa na-adịghị ike. Ụgbọ mmiri ikuku na-arụkarị ọrụ n'okpuru oghere, nke na-enyere aka nkwụsị site n'ibelata nrụgide. Ihe nkedo nke okpukpu abụọ na-emekwa ka ngwakọta ahụ dịkwuo mma site na ịpịkọta na ibelata plastik. Usoro a na-emepụta agbaze nke edo. Ndị na-arụ ọrụ ga-edozirịrị mmepụta n'etiti usoro abụọ ahụ ka ịzenarị mpụta ma ọ bụ ikuku idei mmiri. Atụmatụ ndị a na-eme ka otu screw extruder ventilashị rụọ ọrụ nke ọma na nke a pụrụ ịdabere na ya na ngwa ụlọ nyocha.

Mara: Mpụta kwụsiri ike na iji ike dị ala na-ewepụta ndị na-apụ apụ iche na gburugburu nyocha.

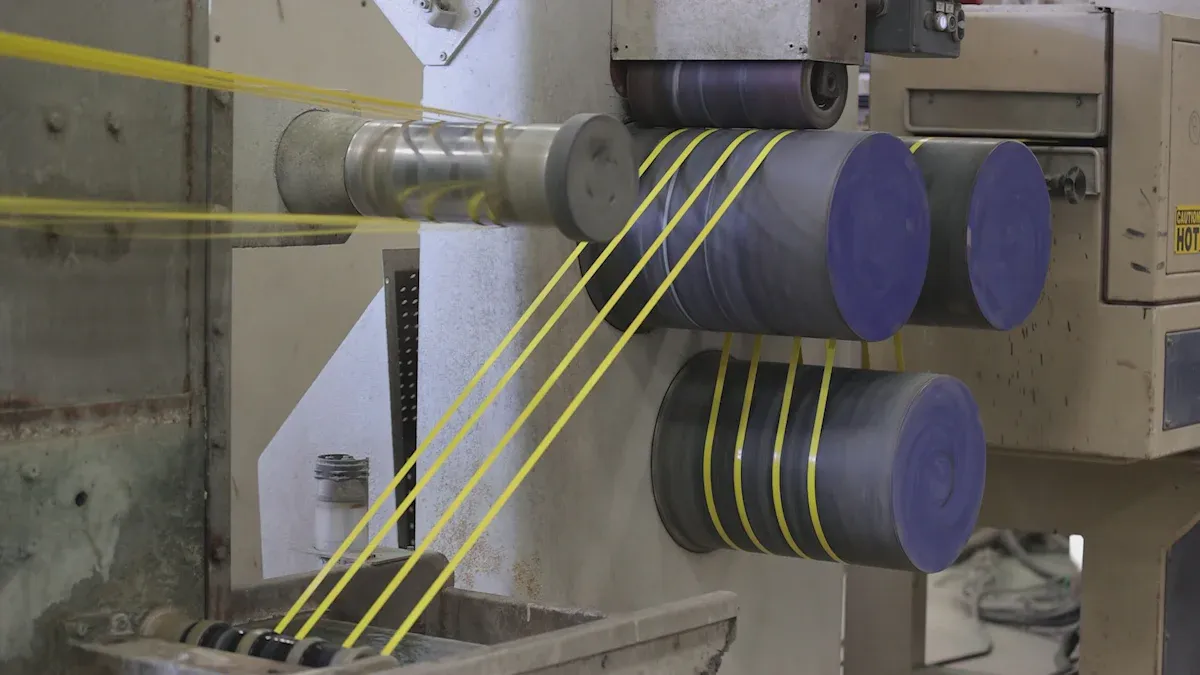

Igwe otu ihe ịghasa

Igwe otu ihe nkedo na-ekpuchi ọtụtụ ihe ndị na-emepụta ihe maka ịgbaze, ịgwakọta, na ịkpụzi polymers. Igwe ndị a na-enye nhazi dị mfe na ịrụ ọrụ dị mfe. Ndị na-eme nchọpụta nwere ike ijikwa shear na okpomọkụ nke ọma, nke na-enyere aka na usoro polymer isi na ọrụ extrusion. Igwe otu ihe nkedo na-arụ ọrụ nke ọma maka ịme tubing, ihe nkiri na ngwaahịa ndị ọzọ dị mfe. Ha na-abịa na nha na nhazi dị iche iche iji kwekọọ mkpa nyocha dị iche iche.

| Ụdị Extruder | Isi atụmatụ na uru | Ngwa a na-ahụkarị na dabara adaba |

|---|---|---|

| Otu ịghasa Extruders | Nhazi dị mfe, njikwa dị mma, ọrụ dị mfe | Tubing, ihe nkiri, ihe ndabere polymer |

| Ejima ịghasa Extruders | Ngwakọta kachasị elu, skru na-agbanwe agbanwe, na-ejikọta ọnụ | Ngwakọta, ihe mgbagwoju anya, ọgwụ ọgwụ |

| Miniature/Micro Extruders | Obere-ọnụ ọgụgụ, ọnụ ahịa bara uru, ntụkwasị obi | R&D, prototyping, obere ihe samples |

Igwe granulator enweghị mmiri

Igwe granulator na-enweghị mmiri na-atụgharị ihe plastik ka ọ bụrụ granules na-ejighị mmiri. Nkà na ụzụ a na-eme ka ike dị ike ma na-ebelata mmetụta gburugburu ebe obibi. Usoro ahụ na-eme ka granules dị ọcha ma dị ọcha, nke na-erite uru nhazi usoro ọzọ. Igwe granulator enweghị mmiri na-ejikwa ọtụtụ ụdị resin rọba. Ha na-enyere ndị na-eme nchọpụta aka ịmepụta granules dị elu maka ule na mmepe.

Usoro Mpụpụ Polymer Nzọụkwụ-Nzọụkwụ

Na-eri ihe Polymer

Usoro extrusion na-amalite site n'itinye ihe onwunwe polymer nri n'ime nri hopper. The hopper na-ahụ na ọbụna nkesa na-egbochi blockages, nke na-enyere aka ịnọgide na-enwe na-esi nri. Ihe nkedo dị n'ime gbọmgbọm ahụ na-amalite ịtụgharị, na-adọta pellets polymer ma ọ bụ ntụ ntụ n'ihu. Nhazi nke ịghasa, gụnyere dayameta ya na ogologo-na-dayameta ruru, na-arụ ọrụ dị mkpa n'otú ihe ahụ si aga nke ọma. Usoro nchịkwa na-enye ndị na-arụ ọrụ aka ịhazigharị ọsọ ọsọ na ọnụego nri, nke na-enyere aka mee ka usoro ahụ dị mma maka polymers dị iche iche.

- Emebere ihe ndị na-enye nri iji gbochie mkpọchi ma hụ na nri dị mma.

- Ihe nkedo ahụ na-ebufe, na-akpakọ ma malite ikpo polymer.

- Njikwa okpomọkụ na gbọmgbọm na-enyere aka ịkwalite usoro mgbaze.

Nchoputa mbu gosiputara na ijikwa oso oso na okpomoku na-emetụta otu polymer na-eri nri na agbaze. Ndị na-ebupụ ụlọ nyocha ọgbara ọhụrụ na-eji njikwa dị elu mee ka nri na-aga nke ọma ma kwụsie ike.

Na-agbaze na Plasticizing

Ka polymer na-aga n'akụkụ gbọmgbọm ahụ, ọ na-abanye na mpaghara ọkụ. Ọnọdụ okpomọkụ dị na mpaghara ọ bụla na-abawanye nwayọọ nwayọọ, na-eme ka polymer dị nro ma gbazee. Ntụgharị nke ịghasa na okpomọkụ nke gbọmgbọm ahụ na-arụkọ ọrụ ọnụ iji mee ka ihe ahụ mee plastik, na-atụgharị ya ka ọ bụrụ otu ihe a wụrụ awụ. Ihe mmetụta etinyere n'akụkụ gbọmgbọm ahụ na-enyocha ma ọnọdụ okpomọkụ yana nrụgide iji hụ na polymer gbazere n'ime oke nhazi ya dị mma.

| Oke | Nkọwa |

|---|---|

| Agbazekwa okpomọkụ | Ga-anọrịrị n'ime oke nhazi polymer maka nsonaazụ kacha mma. |

| Nrụgide N'elu Screw | Na-egosi ogo agbaze na nkwụsi ike usoro. |

| Mgbanwe nrụgide | A na-enyocha ya iji chọpụta nsogbu ọ bụla nwere mgbaze ma ọ bụ eruba. |

| Mgbanwe okpomọkụ | Esorola iji hụ na ọbụna kpo oku ma zere ntụpọ. |

| Ogo nke agbaze | A na-enyocha ihe nkiri ma ọ bụ nwalee ihe nkiri extruded maka idoanya na ịdị n'otu. |

| Ndekọ arụmọrụ screw | Na-ejikọta ihe ndị a iji tụọ ogo agbaze site na dara ogbenye (0) ruo nke ọma (1). |

Njikwa ziri ezi nke okpomọkụ na nrụgide na-enyere aka igbochi mmebi ma hụ na agbaze na-agbanwe agbanwe. Nleba anya n'ezie na ihe mmetụta dị elu na usoro spectroscopy na-enye data na-aga n'ihu, na-ekwe ka ndị nchọpụta gbanwee ntọala dịka ọ dị mkpa.

Ịgwakọta na ibufe

Ozugbo agbazere, a ga-agwakọta polymer nke ọma iji hụ na ịdị n'otu. Nhazi nke ịghasa, gụnyere atụmatụ dị ka akụkụ mgbochi ma ọ bụ ngwakọta mpaghara, na-enyere aka ịgwakọta ihe ahụ ma wepụ ihe ọ bụla siri ike fọdụrụnụ. Ka ịghasa na-agbagharị, ọ na-ebuli polymer a wụrụ awụ gaa n'ihu, na-ebuga ya na anwụ.

Ndị na-eme nchọpụta na-eji ntọala dị elunlele ọdụ ụgbọ mmiri na ihe nchọpụta anyaiji mụọ otú ihe ahụ si agwakọta nke ọma. Site n'ịgba ndị na-achọpụta ihe na ịlele ka ha si gbasaa, ha nwere ike ịhụ ka ọsọ ọsọ na geometry si emetụta ngwakọta. Nnukwu ịghasa ọsọ nwere ike mgbe ụfọdụ ịhapụ iberibe siri ike, ma pụrụ iche ịghasa aghụghọ na-eme ka ịgwakọta ma gbochie okwu a.Ihe mmetụta nrụgide n'akụkụ gbọmgbọm ahụtụọ otú polymer si aga nke ọma, na-enyere ndị ọrụ aka ịkwalite usoro ahụ.

Ịkpụzi Site na Die

Polima a wụrụ awụ na-eru anwụ, nke na-akpụzi ya n'ụdị achọrọ. Nhazi nke anwụ na-ekpebi nha ngwaahịa ikpeazụ na ogo elu. Ndị injinia na-eji kọmpụta simulations na nyocha ihe nwere ngwụcha na-emepụta ọnwụ nke na-emepụta ụdịdị ziri ezi ma na-ebelata ntụpọ. Ha na-ebulikwa geometry ọwa mmiri na-erugharị ka ọ kwụzie ọsọ wee belata ọdịiche ntụgharị nke mkpụrụ ndụ, nke nwere ike imetụta akụkụ ngwaahịa ahụ.

| Akụkụ ihe akaebe | Nkọwa |

|---|---|

| Nleba anya nke mmecha | A na-eji amụ ihe na-erugharị ma na-akpụzi izi ezi na anwụ anwụ. |

| Nhazi kacha mma | Na-ebelata mperi ma na-emezi nhazi geometric. |

| Nkwado nnwale | Na-akwado njikwa ike nke akụkụ ngwaahịa. |

| Ntugharị ọnụọgụgụ | Amụma anwụ zaa na interface mmegharị maka mma pụta. |

| Njikwa nhazi nke molecular | Ntụle na-asọpụta iji gbochie ịgbatị na-enweghị isi na mgbanwe ọdịdị. |

Njikwa ziri ezi nke akụrụngwa anwụ na mgbada na-eme ka ngwaahịa ahụ pụọOtu ịghasa Extruderna ezi udi na size.

Na-ajụ oyi na ịkwado

Mgbe emechara ya, polymer na-ekpo ọkụ na-apụ na anwụ wee banye na oge oyi. Igwe oyi na-eme ka polymer sie ike, na-ekpochi ya na ọdịdị ikpeazụ ya na ihe onwunwe ya. Ọnụego jụrụ oyi na-adabere na okpomọkụ extrusion, ọnọdụ gburugburu, na ọsọ nke ngwaahịa na-agafe na mpaghara jụrụ oyi.

| Oke/ Akụkụ | Nleba anya/ Nsonaazụ |

|---|---|

| Extrusion okpomọkụ | Polymer na-ekpo ọkụ na 100 Celsius |

| Ọnọdụ okpomọkụ | A na-edobe ihe dịka 20 Celsius C n'oge nnwale |

| Ọnụọgụgụ jụrụ oyi kacha elu | Ihe dịka 72 Celsius C |

| Mmetụta nke ọsọ | Ọdịda ndị dị ala na-ajụ oyi ma gbatịa oge ike |

| Omume ọnụego jụrụ oyi | Ọnụ ọgụgụ kacha elu na-agbada ka ọsọ na-ebelata; ọnụ ọgụgụ kasị elu na-agbanwe ruo ogologo oge |

| Mmetụta ọtụtụ oyi akwa | N'ígwé ndị ọzọ nwere ike ime ka ndị mbụ kpoo ọkụ, na-eme ka adhesion dịkwuo mma |

Idokwa mpaghara jụrụ oyi n'ime oke okpomọkụ dị warara, mgbe mgbe n'ime ± 2 Celsius, na-enyere aka hụ na ịdị mma ngwaahịa na-agbanwe agbanwe. Iju oyi kwesịrị ekwesị na-egbochi agha ma na-eme ka polymer sie ike nke ọma.

Ngwa nke Single Screw Extruder na nyocha polymer

Nhazi ihe na Nnwale

Ndị na-eme nchọpụta na-eji extruders ụlọ nyocha mepụta ma nwalee ngwakọta polymer ọhụrụ. Ọmụmụ ntọala na patent na-akọwa otúịghasa imewena njikwa okpomọkụ na-eme ka mgbaze na ngwakọta. Nkwalite ndị a na-enyere ndị ọkà mmụta sayensị aka ịmepụta ihe ọhụrụ nwere njirimara ụfọdụ. Dịka ọmụmaatụ, onye na-emepụta ihe na-adịghị ike nke e ji ihe ndị dị n'ógbè ahụ rụọ ọrụ na-egosi arụmọrụ siri ike na mmepụta ụlọ nyocha. Ọ na-edozi ruo 13 n'arọ kwa elekere ma belata ogige ndị na-achọghị na ngwaahịa ikpeazụ. Nsonaazụ ndị a na-akwado na ndị na-ebupụ ụlọ nyocha na-akwado ma ihe ọhụrụ na njikwa mma na nhazi ihe.

| Oke | Uru/ Nsonaazụ |

|---|---|

| Ntinye aka | 13.0 n'arọ / h |

| Ịghasa Ọsọ | 200 rpm |

| Dayameta Barrel | 40 mm |

| Oke Mgbasawanye | 1.82–2.98 |

| Mbelata ihe mgbochi trypsin | 61.07% -87.93% |

Nkwalite usoro

Ndị na-ahụ maka ụlọ nyocha na-enyere ndị ọkà mmụta sayensị aka ịchọta ntọala usoro kachasị mma maka polymers dị iche iche. Data nnwale gosiri naojiji ike na-adabere na ịghasa ọsọ na ihe onwunwe Njirimara. Site na ịdekọ ike moto na nhazi nhazi, ndị nchọpụta nwere ike imeziwanye ike ike na àgwà ngwaahịa. Nnyocha na-egosikwa na mgbanwe ahụịghasa ọsọna ịgbakwunye ihe ụfọdụ nwere ike imeziwanye otú polymers si agwakọta ma na-asọba. Nchọpụta ndị a na-enyere ndị otu aka ịhazi usoro nchekwa, dị mma na nke enwere ike ịmegharị maka nyocha na mmepụta.

NDỤMỌDỤ: Ịmezi ọsọ skru na ọnọdụ okpomọkụ nwere ike ịhazigharị ojiji ike ma melite ogo ngwaahịa.

Nhazi ngwaahịa dị obere

Ndị na-ekpochapụ ụlọ nyocha na-eme ka ọ dị mfe ịmepụta obere batches nke ngwaahịa ọhụrụ. Otu nwere ike ijikwa ọnọdụ okpomọkụ, nrụgide, na ịghasa ọsọ maka nsonaazụ a pụrụ ịdabere na ya. Ụzọ a na-azọpụta ego ma mee ka mmepe dịkwuo ngwa. Ndị na-eme nchọpụta nwere ike nwalee echiche ọhụrụ ngwa ngwa wee bulie ndị na-aga nke ọma. Kọmpat extruders na-enye ohere maka mgbanwe mgbanwe na ihe ma ọ bụ imewe. Ọganihu na akpaaka na nleba anya oge na-eme ka njikwa usoro dịkwuo mma ma belata n'efu.

- Njikwa ziri ezi n'elu usoro usoro

- Ịdị ọnụ ahịa na ngwa ngwa prototyping

- Mfe mgbanwe maka ihe dị iche iche

- Mma ngwaahịa na ịdị n'otu

Ndụmọdụ arụ ọrụ na nchọpụta nsogbu maka Single Screw Extruder

Ịtọlite Extruder

Ntọlite nke ọma na-eme ka ọrụ a pụrụ ịdabere na ya ma gbasaa ndụ akụrụngwa. Ndị ọrụ nka na-agbaso ihe ndị anzọụkwụ maka ezigbo arụmọrụ:

- Wụnye kposaran'ọnọdụ mbụ ha ma nwalee kposara ọhụrụ na obere ọsọ tupu arụ ọrụ zuru oke.

- hazienjikwa okpomọkụngwá ọrụ mgbe nile maka ngbanwe ziri ezi.

- Jiri mmiri distilled n'ime tankị jụrụ oyi iji gbochie ịchacha ma lelee ọkwa mmiri mgbe mgbe.

- Nyochaa valvụ na eriri igwe solenoid, dochie akụkụ ọ bụla ezighi ezi.

- Chekwaa ndị di na nwunye kwa ụbọchị wee chọpụta na relays mpaghara kpo oku na valves solenoid na-arụ ọrụ nke ọma.

- Kpochapụ tankị na-ekpo ọkụ na ụlọ iyuzucha; dochie mgbanaka akara akara aka dị ka ọ dị mkpa.

- Lelee brushes moto DC ma chebe megide nchara.

- Kpoo ọkụ nke nta nke nta mgbe mmalite ma welie ọsọ nke ịghasa nwayọọ nwayọọ.

- Ghichaa akụkụ ndị na-akpụ akpụ ma mee ka ihe nkedo sie ike mgbe niile.

- Maka nchekwa ogologo oge, tinye griiz mgbochi nchara ma chekwaa skru nke ọma.

NDỤMỌDỤ: Ịgbaso usoro ndị a na-enyere aka ịnọgide na-adị mma ngwaahịa na ogologo ndụ akụrụngwa.

Okwu na ngwọta nkịtị

Ndị ọrụ nwere ike izute ọtụtụ nsogbu n'oge ọrụ. Tebụl dị n'okpuru na-akọwapụta nsogbu na ngwọta nkịtị:

| Ụdị mbipụta | Okwu ndị nkịtị | Ihe kpatara ya | Mgbaàmà | Ngwọta |

|---|---|---|---|---|

| Ọdịda igwe | Mkpọsa rapaara | Mwube ihe, lube adịghị mma | Ibufe moto, mkpọtụ | Dị ọcha, tee mmanụ, nyochaa |

| Ọdịda eletrik | Ọdịda moto | ekpo oke ọkụ, obere sekit | Enweghị mmalite, ikpo oke ọkụ | Nyochaa sistemu, zere ibu ibu |

| Usoro ọdịda | Plasticization na-adịghị mma | Ọsọ dị ala, ọnọdụ adịghị mma | Elu siri ike, afụ | Gbanwee ọsọ, okpomọkụ, ihe |

| Usoro mgbochi | Nlekọta | Enweghị ihicha, nyocha | N/A | Nhazi nhazi oge nhicha, nyocha |

Nleba anya na mmezi mgbe niile na-egbochi ọtụtụ nsogbu. Ndị na-arụ ọrụ kwesịrị ịgbaso ntuziaka ntuziaka mgbe ị na-edozi extrusion die iji zere mmejọ.

Atụmatụ nchekwa

Ọrụ extruder ụlọ nyocha gụnyere ọtụtụ ihe egwu. Usoro nchekwa gụnyere:

- Yiri akụrụngwa nchedo onwe onye dịka akpụkpọ ụkwụ nchekwa na ugogbe anya.

- Izere uwe rụrụ arụ n'akụkụ akụkụ ndị na-akpụ akpụ.

- Ịkwado ngwa eletriki niile site n'aka ndị ọrụ ruru eru.

- Idobe ala akọrọ na iji ikpo okwu ma ọ bụ ọwa mmiri iji gbochie ntọhapụ.

- Ịwụnye ihe nchekwa na akụkụ ndị na-akpụ akpụ iji chebe aka.

- Iji ahịrị mmalite maka threadi kama inye nri aka.

Mara: Ọzụzụ nchekwa siri ike na-ebelata ihe egwu nke ọkụ, mgbaka ọkụ eletrik na mmerụ ahụ n'ibu.

Laboratory extruders na-akwado mma, arụmọrụ polymer nhazi sitenjikwa okpomọkụ, nrụgide na ọsọ ọsọ. Ndị na-eme nchọpụta na-erite uru site na mmepụta obere obere, mbelata ihe mkpofu, na imepụta ngwa ngwa. Nhazi modular na-enyere mgbanwe ngwa ngwa na ịhazi ya. Omume na-agbanwe agbanwe na nlebara anya na nkọwa zuru ezu na-enyere aka nweta nsonaazụ a pụrụ ịdabere na ya na ịkwalite ihe ọhụrụ na nyocha polymer.

FAQ

Kedu ihe polymers nwere ike ime usoro ụlọ nyocha otu ịghasa extruder?

A laabu otu ịghasa extrudernwere ike hazie ọtụtụ thermoplastics, gụnyere polyethylene, polypropylene, polystyrene, na PVC. Ndị na-eme nchọpụta na-ahọrọkarị ihe ndị dabere na ihe achọrọ.

Kedu ka ikuku ikuku si emewanye ogo polymer?

Ịkụ ikuku na-ewepụ mmiri mmirina gas sitere na polymer gbazee. Nzọụkwụ a na-egbochi ntụpọ, dị ka afụ ma ọ bụ ntụpọ na-adịghị ike, ma na-emezi ihe nrụpụta ọrụ nke ikpeazụ.

Kedu ka ndị ọrụ si ejikwa okpomọkụ extrusion?

Ndị na-arụ ọrụ na-edobe ma na-enyocha okpomọkụ gbọmgbọm site na iji usoro njikwa. Ihe mmetụta na-enye nzaghachi ozugbo, na-enye ohere mgbanwe ziri ezi maka agbaze na ịkpụzi polymer na-agbanwe agbanwe.

Oge nzipu: Jul-01-2025