Igwe ntụtụ rọba na-akpụzi skru barrel na-arụ nnukwu ọrụ n'ịkpụzi ogo agbaze na ọsọ mmepụta. Ndị injinia na-elekwasị anya naBarrel Ịkpụzi Ọgwụ Ọgwụimewe iji kwalite arụmọrụ. Ha na-eji ihe dị iche iche eme iheIgwe anaghị agba nchara nke otu Screw Plastic ExtrudernaIgwe mwepu nke otu ihe. Nhọrọ ọ bụla na-enyere igwe aka ịhazi plastik nke ọma.

Nrụpụta na arụrụ ọrụ n'ịkpụzi ịgba ọgwụ mgbochi mmiri rọba

Ụdị Barrel: Bimetallic vs. Integral

Ịhọrọ ụdị gbọmgbọm ziri ezi nwere ike ime nnukwu ọdịiche na otu aPlastic injection molding skru barrelna-eme. Bimetallic barel na-eji isi nchara siri ike nwere mkpuchi alloy siri ike n'ime. Nhazi a na-echekwa ihe ndị bara uru ma na-ahapụ ndị na-emepụta ihe dochie naanị ihe mkpuchi a na-eyi, nke na-eme ka nlekọta dị mfe ma dịkwuo ọnụ ahịa. Ọdịmma dị n'etiti mkpuchi na gbọmgbọm ahụ ga-abụrịrị nkenke iji mee ka okpomọkụ na-aga nke ọma ma gbochie mmegharị ahụ. Bimetallic barel na-arụ ọrụ nke ọma maka nhazi abrasive ma ọ bụ plastik siri ike n'ihi na ha na-eguzogide iyi ma na-adịte aka.

A na-eme mkpọmkpọ ọnụ dị ka otu ibe. Nke a na-enye ha oke nkenke na ọbụna okpomọkụ nkesa n'akụkụ gbọmgbọm. Ha na-eme ka ọ dịkwuo mfe ịwụnye na ịnọgide na-enwe usoro kpo oku na oyi. Agbanyeghị, ha chọrọ njikwa nrụpụta siri ike ka ịdị mma dị elu. Mgbe ị na-atụnyere abụọ ahụ, gbọmgbọm integral na-enye nrụzi dị mfe na kpo oku otu, ebe barel bimetallic na-enye nguzogide iyi ka mma yana ngbanwe akụkụ dị mfe.

| Akụkụ arụmọrụ | Ngwakọta gbọmgbọm | Bimetallic Barrel |

|---|---|---|

| Ihe owuwu | Otu-ibe, elu nrụpụta nkenke | Base gbọmgbọm na replaceable alloy ígwè bushing |

| Nkesa okpomọkụ | Nkesa okpomọkụ n'ụdị n'akụkụ axis gbọmgbọm | A na-echekwa ọkụ ọkụ ma ọ bụrụ na ọ dabara nke ọma |

| Yiri Nguzogide | Ọkọlọtọ iyi mgbochi | Nguzogide iyi emelitere n'ihi mkpuchi nchara alloy |

| Nlekọta | Nrụnye dị mfe na mmezi nke usoro kpo oku / oyi | Nkịta nwere ike dochie anya na-enye ohere ngbanwe akụkụ dị mfe |

| Eji ihe eji eme ihe | Na-achọ izi ezi dị elu na ịdị mma ihe onwunwe | Na-echekwa ihe ndị bara uru site na iji ígwè alloy naanị na mkpuchi |

Orù mmiri bimetallic na-adịru ogologo oge karịa gbọmgbọrọ agbakwunyere, ọkachasị mgbe a na-ahazi ihe ndị siri ike. Nhazi ha na-ebelata oge nkwụsịtụ na ụgwọ nnọchi anya, nke na-enyere aka mee ka mmepụta na-aga nke ọma.

Geometry screw: R/D Ratio, Ratio Compression, and Flight Design

The geometry nkeịghasa n'ime Plastic Injection ịkpụzi ịghasa gbọmgbọmna-akpụzi ka plastik si agbaze na mix. Ogo L/D, nke na-atụnyere ogologo ịghasa na dayameta ya, na-emetụta ịdị n'otu na ngwakọta. Ogologo ogologo ogologo (oke L / D dị elu) na-enye plastik karịa oge iji gbazee na ngwakọta, nke na-eme ka mma ngwaahịa dịkwuo mma. Otú ọ dị, ọ bụrụ na ịghasa ahụ dị ogologo, ọ nwere ike ịkpata mmebi okpomọkụ, karịsịa na plastik na-ekpo ọkụ. Akụrụngwa dị ka PVC na POM chọrọ skru dị mkpụmkpụ iji zere mmebi, ebe plastik jupụtara na iko ma ọ bụ viscosity dị elu na-erite uru site na skru ogologo na mpaghara agwakọta siri ike.

- Akụrụngwa nwere ezigbo nkwụsi ike na-ekpo ọkụ na-eji skru ogologo maka ịgwakọta ka mma.

- Plastics nwere mmetụta ọkụ chọrọ skru dị mkpụmkpụ ma ọ bụ atụmatụ eri pụrụ iche.

- skru ebumnuche izugbe (L/D ~ 20:1) dabara plastik nkịtị mana nwere ike igosi mgbanwe agba.

- Ihe mgbochi mgbochi (L/D ~ 24: 1) na-emezi ngwakọta maka plastik agbadoro.

- Ihe nkewa nkewa (L / D ~ 18: 1) na-enyere ihe ndị na-ekpo ọkụ na-ekpo ọkụ aka izere mmebi.

- Ngwakọta kposara (L / D ~ 22: 1) na-enye agbaze edo maka plastik pụrụ iche.

Oke mkpakọ na-atụ ole ihe nkedo ahụ na-akpakọba rọba. Plastics nwere viscosity dị elu chọrọ oke mkpakọ dị elu iji gbazee ma gwakọta nke ọma. Ịmezi oke mkpakọ na-enyere aka ịhazi ntinye na ịdịmma ngwaahịa. Ndị na-emepụta ihe na-enyochakarị ma na-ebuli nhazi nke skru ka ọ dabara na mkpa ihe ahụ.

Nhazi ụgbọ elu dịkwa mkpa. Skru ndị emeziri nke ọma na-eme ka ogo gbazee dị mma site n'ikwekọ n'omume nke polima. Sistemu nnyefe agbaze agbaze ejirila na-enyere aka ịchịkwa okpomoku agbaze na viscosity, na-ebelata ohere nke mmebi. Ịgwakọta skru na ihe mgbochi dị ike na-enye agbaze otu ma gbochie ntụpọ nwụrụ anwụ, nke na-eme ka plastik ghara ikpo ọkụ ma ọ bụ gbanwee agba.

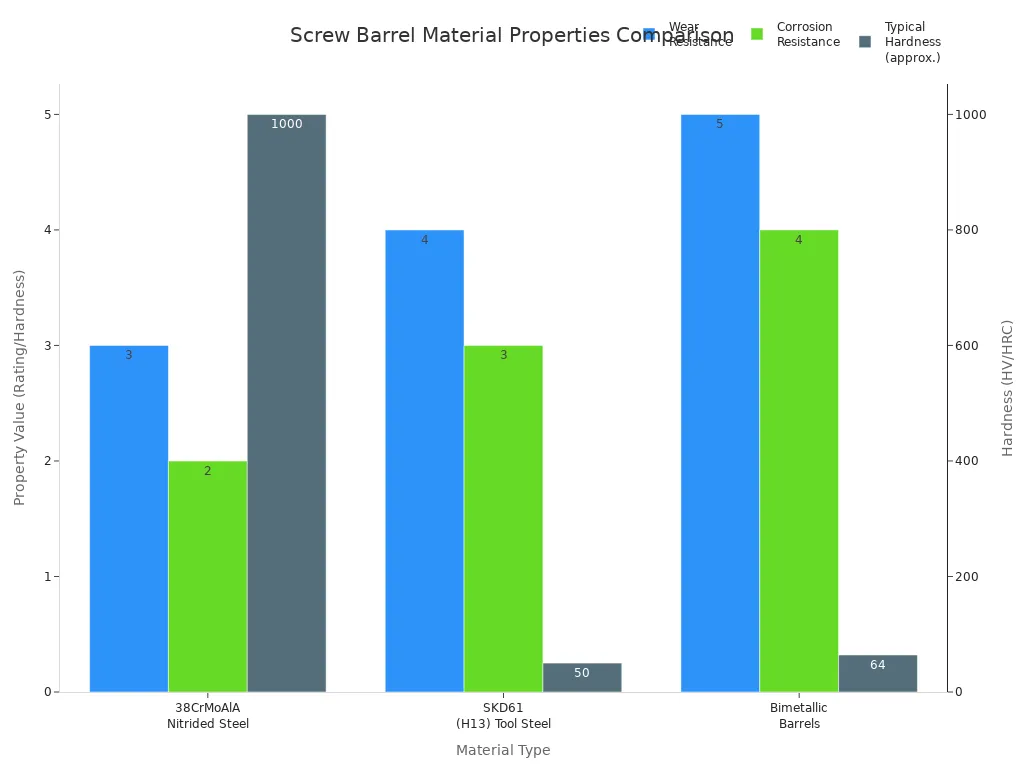

Ngwakọta ihe na ọgwụgwọ elu

Ngwa ndị a na-eji kpụọ gbọmgbọm ịhịa aka n'ahụ plastik na-emetụta ịdịte aka na arụmọrụ ya. Nitrided ígwè na-enye ezigbo ike ike na iyi nguzogide maka plastik ọkọlọtọ. Barrels Bimetallic na-ejikọta ntọala nchara na eriri alloy, na-enye ọmarịcha iyi na nguzogide corrosion maka plastik siri ike ma ọ bụ jupụtara. Ngwá ọrụ ígwè na-enye ike dị elu ma na-eyi nguzogide maka oke gburugburu.

| Ụdị ihe | Njirimara igodo & Uru | ọghọm & oke | Ngwa kacha mma |

|---|---|---|---|

| Nitrided ígwè | Isi ike elu elu; ezigbo mkpuchi mkpuchi maka resin na-ejupụtaghị; ọnụ ala | Nguzogide corrosion na-adịghị mma; adịghị mma maka abrasive/chemical resins | Akpụkpọ anụ dị ka polyethylene, polypropylene |

| Bimetallic Barrel | Nkwado ígwè na ihe mkpuchi alloy; ezigbo eyi na nguzogide corrosion; ogologo ndụ | Dị oke ọnụ; nwere ike ibu oke maka ojiji izugbe | Naịlọn jupụtara iko, ABS na-ere ọkụ, PVC, polymers ike ike |

| Alloys dabeere na nickel | Nguzogide corrosion pụrụ iche; dị mma maka resins halogenated na-ere ọkụ | Ihe na-esighị ike karịa alloys dabeere na ígwè; ala eyi iguzogide | Ndị polymer na-eme ihe ike |

| Alloys dabeere Iron | Isi ike na iyi nguzogide | Nguzogide corrosion dị ala karịa alloys dabere na nickel | Abrasive, resins jupụtara nke ukwuu |

| Ngwá Ọrụ Steel | Isi ike na ike pụrụiche; elu eyi iguzogide | Ọnụ ego dị elu; dị mfe na corrosion na-enweghị mkpuchi | Oke iyi gburugburu, ngwa mmepụta dị elu |

| Barrel Ekpuchiri Ọpụrụiche | Mkpuchi dị ka tungsten carbide ma ọ bụ chrome plating na-eme ka ike na-eyi na mgbochi corrosion dịkwuo mma | Na-agbakwụnye ọnụ ahịa na mgbagwoju anya; mkpuchi mkpuchi dịgasị iche iche | Ngwa resin omenala ma ọ bụ ike ike |

Ọgwụgwọ dị n'elu dị ka nitriding na chrome plating na-ebuli nguzogide na ogologo ndụ. Nitriding nwere ike okpukpu abụọ ma ọ bụ okpukpu atọ ndụ ọrụ nke skru na gbọmgbọm. Ihe mkpuchi chrome na-abawanye ike na nguzogide corrosion, mana nitriding na-arụkarị ọrụ nke ọma n'okpuru ọnọdụ abrasive. Ịfesa molybdenum na nitriding na-enye ọbụna nchebe karịa. Ịrụ ọrụ nke ọma na nrụzi na-enyere aka ịbawanye uru ndị a.

Ọdụ ụgbọ mmiri na-enye nri na imepụta ikuku

Nhazi ọdụ ụgbọ mmiri na-achịkwa ka plastik si abanye na gbọmgbọm. Ezigbo njikwa okpomọkụ n'ọdụ ụgbọ mmiri nri na-eme ka viscosity ihe na-aga n'ihu, nke na-enyere aka ịnọgide na-erugharị na nri na-agbanwe agbanwe. Ndị na-ebu oghere na ndị na-anata hopper na-ahụ na ihe na-aga nke ọma n'ime igwe, na-ebelata mmetọ na mwụfu. Ntọlite a na-eme ka mmepụta ihe dị elu na nri na-agbanwe agbanwe.

- Ndị na-ebu ihe na-ekpu ọkụ na-arịgoro ozugbo na akpịrị igwe, na-ebelata mmetọ.

- Ndị na-anata hopper na-eji ike ndọda azụ ihe, na-eme ka usoro ahụ dị mfe.

Imepụta ikuku ikuku na-arụkwa ọrụ dị mkpa. Ihe nkedo ikuku nwere mpaghara pụrụ iche nke na-ewepụ mmiri na ihe na-agbanwe agbanwe n'oge nhazi. Nke a dị mkpa maka ihe hygroscopic na plastik emegharịrị. Ọdụ ụgbọ mmiri na-ekupụ ikuku na-eme ka ikuku na mmiri gbapụ, na-egbochi ntụpọ na idobe ịdị mma extrusion dị elu.

Ndụmọdụ: ọdụ ụgbọ mmiri na-enye nri kwesịrị ekwesị na imewe ikuku na-enyere aka ịnọgide na-emepụta ihe na-aga n'ihu ma melite ogo ngwaahịa, karịsịa mgbe ị na-arụ ọrụ na plastik emegharịrị ma ọ bụ nke nwere mmetụta.

Nsonaazụ arụmọrụ nke Plastic Injection Molding Screw Barrel Design

Agbaze Ogo na Homogeneity

Igwe mmiri plastik a haziri nke ọma na-akpụzi skru barrel na-enyere aka mee ka ọ dị nro na ọbụna gbazee. Jiometry nke ịghasa, gụnyere yaoke mkpakọna ọdịdị nke mpaghara ya, na-achịkwa otú pellets plastik si agbaze na ngwakọta. Mgbe oke mkpakọ dabara na ihe ahụ, agbaze na-aga nke ọma. Nke a na-ebelata nsogbu dị ka akara splay ma ọ bụ agbaze ezughị ezu. Nkempaghara nrina-akpali ma na-ekpo ọkụ na pellets, mpaghara mkpakọ na-agbaze ma na-agbanye ihe ahụ, na mpaghara metering na-eme ka agbaze ahụ dị ọbụna. Atụmatụ dị ka omimi ọwa na ngalaba agwakọta na-enyere aka kposara ikpo ọkụ na ịgwakọta plastik. Ihe mgbochi mgbochi nwere ike ikewapụ plastik siri ike na gbazere, na-eme ka agbaze dịkwuo mma ma na-azọpụta ike.

Mgbe agbaze ahụ bụ otu, ngwaahịa ikpeazụ na-ele anya nke ọma ma rụọ ọrụ nke ọma. Ngwakọta na-adịghị mma nwere ike ime ka eriri agba, ntụpọ adịghị ike, ma ọ bụ mgbanwe na nha akụkụ. Ezi agbaze homogeneity pụtara obere ntụpọ na akụkụ ndị ọzọ a pụrụ ịdabere na ya. Ndị na-arụ ọrụ nwekwara ike iji sensọ na-ekiri ogo agbaze ma mezie ntọala maka nsonaazụ kacha mma.

- Ịgwakọta agbaze na-adịghị mma na-akpata streaks agba na ntụpọ adịghị ike.

- Ogo agbaze dị mma na-eduga na nha akụkụ na ike na-agbanwe agbanwe.

- Ogo agbaze na-adabere na okpomoku gbọmgbọm, ọsọ ịghasa, na nrụgide azụ.

Cheta na: Idobe okpomọkụ gbazee na-adaba na ụdị rọba ahụ na-enyere aka izere ntụpọ ma mee ka ịdịmma ngwaahịa dị elu.

Ịgwakọta arụmọrụ na Oge okirikiri

Ịgwakọta arụmọrụ dabere n'ụdị ịghasa na njirimara pụrụ iche. Ka ịghasa na-atụgharị, ọ na-akwagharị ma na-apịaji plastik, na-emepụta ikeshiee agha. Ịgwakọta akụkụ dị nso n'ọnụ ọnụ, dị ka ntụtụ ma ọ bụ ụgbọ elu ihe mgbochi, na-enyere aka ịgwakọta agbaze. Omume a na-agbasa agba na mgbakwunye n'otu n'otu, ya mere akụkụ ikpeazụ na-ele anya nke ọma na otu. Ihe mgbochi mgbochi na-eji ụgbọ elu nke abụọ kewapụ plastik gbazere na ibe ndị siri ike, na-agbaze ngwa ngwa ma na-egbochi nchichi agbazebeghị.

- Screw geometry na-achịkwa otú pellet si aga, gbazee, na ngwakọta.

- Akụkụ ngwakọta na-emepụta mmegharị looping,na-agwakọta ihe karịrị 95%nke ihe ngwa ngwa.

- Ihe mgbochi mgbochi na atụmatụ pụrụ iche na-enyere aka ịgbasa agba na mgbakwunye.

Ịgwakọta arụmọrụ na-emetụtakwa oge okirikiri. Ngwa ngwa na ọbụna na-agbaze pụtara na igwe nwere ike na-agba ọsọ cycles na obere oge. Iji skru mgbochi, skru dayameta buru ibu, ma ọ bụ oghere dị omimi na-abawanye ọsọ plastik. Ịwelite ọsọ ọsọ (mgbe ọ dị mma maka ihe) na ibelata nrụgide azụ nwekwara ike ime ka oge okirikiri dị mkpụmkpụ. Sistemụ kpo oku na oyi dị elu na-eme ka gbọmgbọm ahụ dị mma, na-enyere akụkụ aka oyi ngwa ngwa ma na-eme ka mmepụta na-aga n'ihu.

- Nhazi nke screw barrel kacha mma na-egbochi mkpọchi na igbu oge.

- Usoro kpo oku na nke ọma na-enyere akụkụ aka ike ngwa ngwa.

- Ihe na-adịgide adịgide na mkpuchi na-ebelata oge nkwụsị maka nrụzi.

Yiri Nguzogide na Nlekọta

Wear bụ nnukwu nchegbu maka ọ bụla Plastic Injection ịkpụzi skru barrel. Ihe nchacha abrasive, rọba na-emebi emebi, na ogologo oge na-arụ ọrụ nwere ike imebi ihe nkedo na gbọmgbọm. Ụdị ejiji ndị a na-ejikarị eme ihe na-agụnye uwe nrapado, eyi ihe na-ekpo ọkụ na corrosion. Dịka ọmụmaatụ, akwa abrasive na-eme mgbe ihe ndị siri ike dị ka eriri enyo na-ete ígwè ahụ. Uwe na-emebi emebi na-abịa site na kemịkalụ na plastik dị ka PVC.

| Yiri usoro | Nkọwa | Atụmatụ Mbelata chepụta |

|---|---|---|

| Yiri nrapado | Metal na-ebupụta kọntaktị na nyefe ihe. | Jiri alloys na-eche ihu siri ike, lelee maka akara, hụ na ndakọrịta ihe. |

| Uwe abrasive | Omume ịkpacha ihe site na pellets ma ọ bụ ihe ndochi. | Jiri alloys siri ike, zere ihe ndị na-emebi emebi, mee ka nri nri dị ọcha. |

| Uwe na-emebi emebi | Mwakpo kemịkalụ sitere na plastik ụfọdụ. | Jiri ihe na-eguzogide corrosion, zere kemịkalụ siri ike. |

| Okwu Ndozi | Mmejọ na-akpata ịhịa aka n'ahụ na iyi na-enweghị isi. | Gbaa mbọ hụ na kwụ ọtọ na nhazi nke ọma. |

Nhọrọ ihe na ọgwụgwọ elu na-eme nnukwu ọdịiche. Liquid nitriding na-abawanye ike ike elu ma na-eyi nguzogide. Ogwe bimetallic nwere ihe mkpuchi pụrụ iche na-adịte aka, ọkachasị na plastik siri ike. Nlele anya na mgbochi mgbochi, dị ka ihicha na ịlele nhazi, na-enyere aka ị nweta nsogbu n'oge. Ihe mkpuchi dị elu na ihe ọhụrụ nwere ike ịgbatị ndụ gbọmgbọm ruo 40%, na-ebelata ụgwọ ọrụ nlekọta na ibelata oge nkwụsị.

- Ugboro mmezi na-adabere na ihe mkpuchi gbọmgbọm na mkpuchi.

- Nlekọta mgbochi na nyocha oge niile na-agbatị ndụ gbọmgbọm.

- Usoro ọgwụgwọ elu dị elu na-ebelata nrụzi na ngbanwe.

Ndakọrịta na ngwa na ngwa dị iche iche

Nhazi gbọmgbọm mkpọsa na-agbanwe agbanwe na-eme ka ndị na-emepụta ihe hazie ọtụtụ ụdị plastik. Enwere ike gbanwee geometry screw, dị ka ogologo, pitch, na omimi ọwa, ka ọ dabara na ihe dị iche iche. Ebumnuche izugbe, ihe mgbochi, na skru agwakọta nke ọ bụla na-arụ ọrụ kacha mma na ụfọdụ plastik. Usoro jụrụ oyi, dị ka ọwa mmiri, na-edebe gbọmgbọm ahụ na okpomọkụ kwesịrị ekwesị maka ihe ọ bụla.

- Ịkpọsa imewe na geometrydakọtara plastik dị iche iche.

- Usoro jụrụ oyi na-egbochi ikpo oke ọkụ.

- Alloys dị elu na mkpuchi na-edozi ọnọdụ siri ike.

Nhazi nwere ike ime na-emekwa ka ọ dị mfe ịgbanwe n'etiti ọrụ. Njirimara dị ka ihe nkwụnye akwụpụ ngwa ngwa na screw pushers na-enyere ndị ọrụ aka ịgbanwe skru ọsọ ọsọ. Njikwa nhazi mgbanwe na-eji sensọ na mmụta igwe iji dozie ntọala ozugbo. Nke a na-ebelata mgbanwe akwụkwọ ntuziaka ma mee ka mgbanwe mgbanwe dị ngwa, ya mere mmepụta nwere ike ịgbanwe site n'otu ihe ma ọ bụ ngwaahịa gaa na nke ọzọ na obere oge.

NDỤMỌDỤ: Nhazi nke screw barrel na-enyere ụlọ ọrụ aka ijikwa ọtụtụ ụdị plastik ma gbanwee ọrụ ngwa ngwa, na-eme ka mmepụta na-agbanwe agbanwe na ịrụ ọrụ nke ọma.

Ịchọpụta nsogbu ndị na-arụkarị ọrụ

Ọbụna na nhazi kachasị mma, nsogbu nwere ike ime. Okwu ndị a na-ahụkarị gụnyereoke iyi, nsogbu okpomọkụ, mgbochi, mkpọtụ, na njehie agwakọta agba. Nsogbu ọ bụla nwere ihe kpatara ya na ihe ngwọta ya.

| Okwu arụmọrụ | Nkọwa na akara ngosi | Ihe kpatara na ngwọta |

|---|---|---|

| iyi oke oke | Ngwunye ihe, adịghị mma, oke okpomọkụ, mkpọtụ | Jiri barel bimetallic, alloys na-eche ihu siri ike, ihicha mgbe niile, nhazi nke ọma |

| Iwu okpomọkụ | Ngbanwe agba, ịcha ọkụ, afụ, ịgba egwu | Kewaa gbọmgbọm n'ime mpaghara, jiri sensọ, kpo oku nwayọ nwayọ, mkpuchi mkpuchi |

| Mgbochi na ewuli elu | Nrụgide dị elu, adịghị mma na-asọpụta, ntụpọ ojii | Jiri ogige mkpocha dị ọcha, ọsọ nke ọma, mechie gbọmgbọm n'oge ọdịda |

| mkpọtụ ma ọ bụ ịma jijiji | Oke mkpọtụ, ịma jijiji, esemokwu | Nyochaa nhazi, bearings, jiri ịma jijiji, kewapụ ihe ndị ahụ |

| Ngwakọta agba/Mmetụta | Ụcha agba, ndò na-ekwekọghị ekwekọ, mmetọ | Jiri ogige nchacha, ihicha mgbe niile, na-ebuli nhazi skru, mechie igwe n'oge mmechi |

Ndị na-arụ ọrụ nwere ike dozie ọtụtụ nsogbu site na ịgbaso usoro igodo ole na ole:

- Bulite nhazi skru na mpaghara okpomọkụ gbọmgbọm.

- Nyochaa ma mezie ọnọdụ okpomọkụ na ịghasa ọsọ.

- Hazie feeders ma gbochie njikota ihe.

- Nyochaa skru na gbọmgbọm maka eyi, ọkachasị na mpaghara nrụgide dị elu.

- Jiri amụma amụma na-eme atụmatụ nrụzi ma belata oge nkwụsị.

- Debe ihe nkedo mapụtarama megharịa naanị ugboro ole na ole.

- Zụọnụ ndị na-arụ ọrụ ụgbọ oloko ka ha hụ akara ịdọ aka ná ntị mbụ.

Mara:Nhicha mgbe niile, mmanu mmanu na nleba anya nke ọmanyere aka mee ka igwe mkpuchi mkpuchi plastik na-agba ọsọ nke ọma ma gbatịa ndụ ya.

Na-ebuli ihe owuwu nke Plastic injection molding screw barrel na-akwalite ogo agbaze na ndụ akụrụngwa. Mgbe ndị nrụpụta na-ahọrọỤdị gbọmgbọm ziri ezi, skru geometry, na ihe, Ha na-ahụ ka ọ na-erugharị n'ụzọ dị nro, ngwakọta ka mma, yana ntụpọ ole na ole. Nlekọta anya mgbe niile, gụnyere ihicha na nyocha, na-eme ka igwe na-arụ ọrụ nke ọma ma na-ebelata ọnụ ahịa.

FAQ

Kedu uru bụ isi uru nke bimetallic screw barrel?

Bimetallic barel na-eguzogide iyi site na plastik siri ike. Ha na-adị ogologo oge ma na-ebelata oge nkwụsị maka mmezi.

Ugboro ole ka ndị na-arụ ọrụ kwesịrị inyocha gbọmgbọm skru?

Ndị na-arụ ọrụ kwesịrị ịlele gbọmgbọm mkpọsa kwa ọnwa. Nleba anya mgbe niile na-enyere aka ijide uwe n'isi ma mee ka igwe na-arụ ọrụ nke ọma.

Otu gbọmgbọm nwere ike iji ọtụtụ ụdị plastik rụọ ọrụ?

| Ụdị gbọmgbọm | Nkwekọrịta |

|---|---|

| Ebumnuche izugbe | Ọ dị mma |

| Ihe mgbochi | Magburu onwe |

| Ngwakọta | Ọ dị ezigbo mma |

gbọmgbọm a haziri nke ọma nwere ike ijikwa ọtụtụ plastik, mana ụfọdụ ihe chọrọ njirimara pụrụ iche.

Oge nzipu: Ọgọst-25-2025