M tụkwasịrị obi na PVC Pipe ịghasa gbọmgbọm maka extrusion n'ihi na ọ na-eji premium alloy ígwè na elu mkpuchi. Ahụrụ m ka njirimara ndị a si enyere ya aka iguzogide okpomọkụ, nrụgide, na iyi. Tụnyere nhọrọ ọkọlọtọ, ọkaibePVC ọkpọkọ otu ịghasa gbọmgbọmna-adịru ihe ruru ugboro isii. M na-adaberekwa na aotu ịghasa gbọmgbọm maka ịfụ ịkpụzina aPE ọkpọkọ extruder otu ịghasa gbọmgbọmmaka ọrụ siri ike.

Ihe na iwu nke PVC Pipe Screw Barrel maka Extrusion

Nhọrọ Alloy Steel adịchaghị

Mgbe m na-ahọrọ PVC Pipe ịghasa gbọmgbọm maka extrusion, m na-elekwasị anya na alloy ígwè. Nchara ziri ezi na-eme ka ihe niile dị iche na ịdịte aka na arụmọrụ. M na-adabere na ihe ndị dị ka38CrMoAlA na 42CrMon'ihi na ha na-enyeelu ike na magburu onwe eyi iguzogide. Nchara ndị a na-ejikwa ọnọdụ siri ike nke extrusion, gụnyere oke okpomọkụ na nrụgide. M na-achọkwa gbọmgbọm nwere liners bimetallic ma ọ bụ igwe anaghị agba nchara mgbe achọrọ m nchebe ọzọ megide corrosion sitere na ogige chlorine nke PVC.

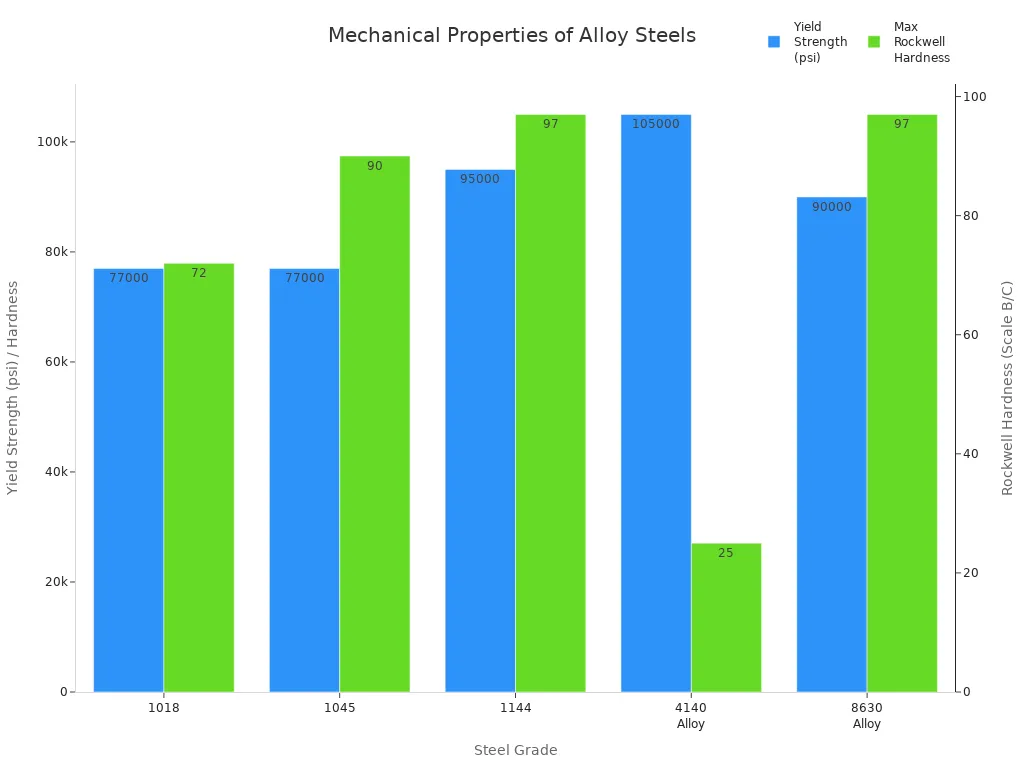

Nke a bụ ụfọdụ nchara alloy ndị a na-ahụkarị na ojiji ha:

| Alloy Steel / ihe | Njirimara isi | Ngwa na PVC Screw Barrels |

|---|---|---|

| AISI 4140 | Ike dị mma, enwere ike ịgwọta okpomọkụ, dị n'ọtụtụ ebe | Ọkọlọtọ maka ọtụtụ gbọmgbọm mkpuchi PVC |

| AISI 4340 | Ike dị elu, ntinye ọgwụgwọ okpomọkụ ka mma | Eji maka ụgbọ elu miri emi ma ọ bụ obere skru dayameta |

| Nitralloy 135-M | Aluminom maka nitriding, nguzogide iyi ka mma | Nitrided elu maka ogologo ndụ |

| 17-4 PH igwe anaghị agba nchara | Ike, corrosion eguzogide | Obere skru chọrọ nguzogide corrosion |

| D2 na H13 Ngwá Ọrụ Steels | Nnukwu nguzogide eyi, ikpo ọkụ na-agwọ ọrịa, na-eguzogide corrosion | Ebe abrasion dị elu, uwe aka, kposara plastik |

| Ngwá Ọrụ CPM (CPM 10V, wdg) | Abrasion kacha elu na nguzogide corrosion | Ngwakọta juru eju, mgbochi iyi na-adịte aka |

Ana m ahọrọ ọkwa nchara mgbe niile dabere na ihe achọrọ nke usoro extrusion. Alloy alloy dị elu na alloys bimetallic na-enye m obi ike na PVC Pipe screw barrel maka extrusion ga-adịgide ruo ọtụtụ afọ nke iji ya dị arọ.

Ọgwụgwọ elu elu na isi ike

Ọgwụgwọ ndị dị n'elu na-ekere òkè dị ukwuu n'ogologo oge mkpọsa mkpọ na-adịru. M na-eji nitriding mepụta akwa oyi akwa na nchara, nke nwere ike iru 70 HRC. Nke a oyi akwa na-eguzogide iyi na nchekasị, ọbụna mgbe gbọmgbọm chere ihu elu nrụgide na okpomọkụ. Ihe mkpuchi chrome na-agbakwunye elu dị larịị ma na-ebelata esemokwu, na-eme ka nhicha dị mfe ma na-eme ka ịgbaze agbaze. Mgbe ụfọdụ, m na-ahọrọ bimetallic alloys ma ọ bụ tungsten carbide mkpuchi maka ọbụna ka ukwuu abrasion iguzogide.

NDỤMỌDỤ: Nitriding na-etolite akwa nitride dị ihe dị ka 0.5-0.8mm miri emi, nke na-echebe gbọmgbọm pụọ na iyi na corrosion. Ihe mkpuchi chrome, nke na-abụkarị 10-50 microns, na-eme ka elu ya dị nro ma na-enyere aka igbochi mmepụta ihe.

Nke a bụ nleba anya ngwa ngwa na ihe arụrụ arụ nke nchara m na-eji:

| Ọkwa ígwè | Ike Mpụta (psi) | Max Rockwell Hardness (Ọnọdụ) | Ihe ndetu na Njirimara na ojiji |

|---|---|---|---|

| 4140 Alloy | 60,000 - 105,000 | C20-C25 | siri ike, ductile, eyi na-eguzogide ọgwụ |

| 17-4 PH igwe anaghị agba nchara | 110,000 | C40 | Ike, corrosion eguzogide |

| Ngwá Ọrụ D2 Steel | 90,000 | C55 | Nnukwu iyi na-eguzogide, corrosion eguzogide |

M na-adakọkarị ọgwụgwọ elu ya na ụdị plastik na ihe mgbakwunye m na-eji. N'ụzọ dị otú a, m PVC Pipe ịghasa gbọmgbọm maka extrusion na-anọgide na ntụkwasị obi na ịrụ ọrụ nke ọma.

Nrụpụta nkenke yana iguzosi ike n'ezi ihe

Imepụta nkenke bụ ọkpụkpụ azụ nke gbọmgbọm ịsa ahụ na-adịgide adịgide. Enwere m ntụkwasị obi na CNC machining na-eme ka nnabata sie ike, mgbe ụfọdụ dịka ± 0.01 mm. Nke a ziri ezi na-eme ka ịghasa na ntupu gbọmgbọm zuru oke, nke dị oke mkpa maka mbufe PVC na ịgwakọta nke ọma. Ana m eleba anya nke ọma na screw geometry — ụgbọ elu, omimi ọwa, pitch, na oke mkpakọ. Atụmatụ ndị a na-enyere m aka ịchịkwa nrụgide na okpomọkụ, na-egbochi mmebi ihe.

- M na-eji akụkụ ikuku ikuku na agwakọta ihe iji wepụ gas ndị tọrọ atọ na ngwakọta ihe mgbakwunye nke ọma.

- Ihe na-ekpo ọkụ na ọwa jụrụ oyi na gbọmgbọm ka m jikwaa mpaghara okpomọkụ, na-eme ka agbaze ahụ kwụsie ike.

- Usoro njikwa jikọtara ọnụ na-enye m ohere inyocha na mezie usoro ahụ ozugbo, na-edobe izi ezi akụkụ na igbochi ntụpọ.

Ọ bụrụ na m achọpụta ụdị uwe ọ bụla ma ọ bụ ngbanwe akụkụ, ana m eme ngwa ngwa. Ọbụlagodi obere mgbanwe nwere ike ibelata ikike mbufe na arụmọrụ plastik, na-eduga na mgbidi ọkpọkọ na-ezighi ezi ma ọ bụ ihe ndị na-agbaze. Site n'ịkwado nkenke, a na m a hụ na m PVC Pipe screw barrel maka extrusion na-ebuga ịdị mma na-agbanwe agbanwe na ogologo ndụ ọrụ.

Nhazi na uru arụmọrụ nke PVC Pipe Screw Barrel maka mkpochapụ

Jiometry kacha mma na nri Uniform

Mgbe m na-ahọrọ PVC Pipe screw barrel maka extrusion, m na-aṅa ntị nke ọma na screw geometry. Nhazi ziri ezi na-enyere m aka nweta nri dị nro na nke edo nke ihe PVC. M na-achọ atụmatụ na-akwado njem na ịgwakọta nke ọma. Nke a bụ ụfọdụ isi ihe imewe m tụlere:

- Ụgbọ elu dị omimi na ọwa dị na mpaghara mbufe na-ebugharị ihe ngwa ngwa n'emeghị ka ọ dị ukwuu.

- Omimi ọwa na-ebelata site na mpaghara mbufe gaa na mpaghara metering, nke na-edozi agbaze na ngwakọta.

- Igwe elu ụgbọ elu buru ibu na-ebugharị ihe ndị ọzọ na obere ike, ebe ihe ndị ọzọ na-enyere aka ịchịkwa usoro na-aga n'ihu ma melite ngwakọta.

- Ngalaba nri na-eme ka ihe na-aga n'ihu ma na-egbochi mgbochi.

- Ngalaba mkpakọ na-agbaze ma gwakọta PVC, na-eji okpomọkụ sitere na esemokwu.

- Nkebi nke metering na-eme ka mmepụta ihe gbazere na-aga n'ihu.

Ana m achọpụta mgbe niile na geometry nke screw dakọtara na njirimara nke PVC na mkpa nke usoro extrusion. Nhazi nke a na-akpachapụ anya na-enyere m aka izere ntụpọ ma na-eme ka ihe na-aga n'ihu na-aga n'ihu.

Ọ bụrụ na m achọpụta uwe ọ bụla na ịghasa, ana m eme ngwa ngwa. Ọbụlagodi obere mgbanwe na geometry nwere ike ibute oke na-ezighi ezi na ntụpọ na ọkpọkọ ikpeazụ. Site n'idebe ihe nkedo n'elu udi, ana m edebe extrusion dị elu ma belata ihe mkpofu.

Sistemụ kpo oku na oyi akwa

Njikwa okpomọkụ dị oke mkpa maka imepụta ọkpọkọ PVC siri ike ma na-agbanwe agbanwe. M na-adabere na sistemu kpo oku na igwe jụrụ oyi arụnyere n'ime gbọmgbọrọ mkpọda. Usoro ndị a na-enyere m aka idobe okpomọkụ nke ọma n'oge ọ bụla nke extrusion.

| Ụdị Sistemu | Nkọwa | Okwu Okwu |

|---|---|---|

| Sistemụ kpo oku | Ụzọ kpo oku eletrik, dị ka ntinye na ikpo ọkụ, etinyere na mpụga gbọmgbọm ahụ | Na-enye okpomọkụ dị mkpa iji gbazee PVC |

| Sistemụ jụrụ oyi | Usoro mmiri ma ọ bụ ikuku jụrụ oyi; ikuku jụrụ oyi maka obere extruders, mmiri maka ndị buru ibu | Na-egbochi ikpo oke ọkụ ma na-eme ka okpomọkụ kwụsie ike |

M na-eji ihe mmetụta okpomọkụ iji nyochaa usoro ahụ ozugbo. Njikwa akpaghị aka na-edozi kpo oku na oyi dị ka ọ dị mkpa. Nhazi a na-eme ka okpomọkụ gbazee guzoro, nke dị mkpa maka ịdịmma ọkpọkọ na nha nha.

- Njikwa okpomọkụ na mpaghara ọ bụla na-eme ka PVC gbazee kpamkpam na nke ọma.

- Okpomọkụ anwụ kwesịrị ekwesị na-egbochi ọkpọkọ ka ọ ghara ịdaba ma ọ bụ gbasie ike ngwa ngwa.

- Usoro dị jụụ na-enyere ọkpọkọ aka idebe ọdịdị ya ma belata nrụgide dị n'ime.

Site na sistemụ ndị a, enwere m ike ịgbanwe ngwa ngwa ka mgbanwe wee zere ntụpọ dị ka mgbidi na-enweghị isi ma ọ bụ ebe siri ike.

Nguzogide iyi, nrụrụ na nrụgide dị elu

Igwe mkpuchi ọkpọkọ PVC maka extrusion na-eche ọnọdụ siri ike ihu. Ana m ahọrọ gbọmgbọm sitere na alloys pụrụ iche yana akwa mkpuchi dị elu iji guzogide iyi na corrosion. Nhazi PVC nwere ike ịhapụ hydrochloric acid, nke na-awakpo ígwè mgbe niile. Iji gbochie nke a, m na-eji barel bimetallic nwere liners bara ụba na nickel na mkpuchi siri ike dị ka tungsten carbide.

- Nrapado na-eme mgbe akụkụ igwe na-ejikọta ọnụ.

- Uwe abrasive na-abịa site na ihe ndozi dị ka eriri iko ma ọ bụ mineral na PVC.

- Ihe na-emebi emebi na-akpata site na kemịkalụ ewepụtara n'oge nhazi.

M na-ahụkwa na ịghasa na ngwa gbọmgbọm dabara. Nke a na-egbochi nsogbu site na ọnụego mgbasawanye dị iche iche mgbe ọkụ. Nleba anya na mmezi mgbe niile na-enyere m aka ịhụ iyi uwe n'oge ma zere imezi nnukwu ihe.

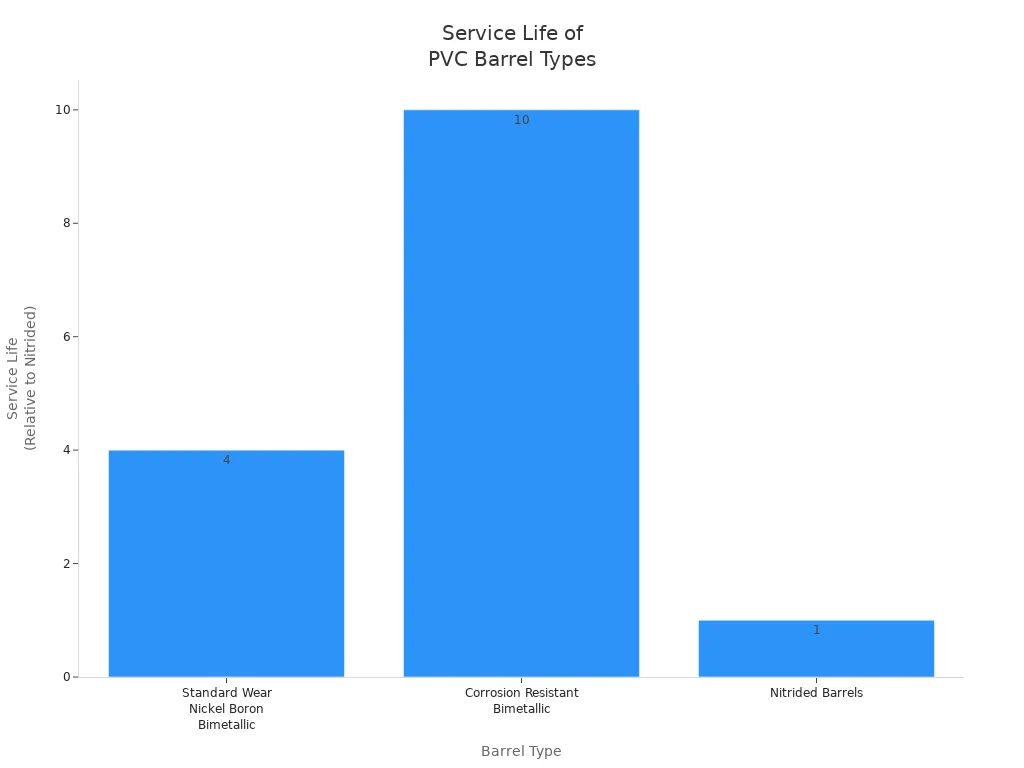

| Ụdị gbọmgbọm | Yiri Nguzogide | Nguzogide corrosion | Ndụ Ọrụ Tụnyere Barrel Nitrided |

|---|---|---|---|

| Ụdị ejiji Nickel Boron Bimetallic | Ezigbo nguzogide abrasion | Nguzogide corrosion na-agafeghị oke | Opekempe 4 ugboro karịa |

| Bimetallic na-eguzogide corrosion | Nguzogide iyi mara mma | Ọ dị mma megide HCl na acid | Ihe karịrị ugboro 10 dị ogologo n'ikuku na-emebi emebi |

| Nitrided Barrels | Isi ike elu elu | Nguzogide corrosion na-adịghị mma | Ntọala (1x) |

Site n'iji ihe ndị a na-emepụta ihe na-emepụta ihe, m na-agbatị ndụ nke ngwá ọrụ m ma na-eme ka mmepụta na-arụ ọrụ nke ọma, ọbụna n'okpuru nrụgide dị elu na ihe abrasive.

Ogo Extrusion na-agbanwe agbanwe yana ndụ ọrụ agbatịkwuru

Amaara m na ịdị mma na-agbanwe agbanwe bụ isi na mmepụta ọkpọkọ PVC. M na-enyocha ihe ndị dị mkpa dị ka okpomọkụ, nrụgide na ọsọ iji mee ka usoro ahụ kwụsie ike. M na-eji ngwa ọrụ ziri ezi lelee akụkụ ọkpọkọ wee chọọ ntụpọ dị n'elu. Sistemu akpaaka na-enyere m aka ijide nsogbu n'isi ma debe usoro ahụ n'ụzọ.

- Ana m eso olu mmepụta, ọnụego ntụpọ, yana ojiji ike iji tụọ arụmọrụ.

- Nlekọta anya na nhazi oge niile na-enyere m aka ịzere oge nkwụsị.

- Ogwe mkpuchi na-adịgide adịgide na mkpuchi bimetallic na-ebelata ugboro ole m kwesịrị ịkwụsị maka ndozi.

Mgbe m na-etinye ego na nnukwu PVC Pipe screw barrel maka extrusion, m na-ahụ obere mmebi na obere mkpofu. Ọnụ ego mmezi m na-agbada, enwere m ike ịhazi ihe ndị emegharịgharịrị ngwa ngwa. M na-achọpụtakwa ojiji ike dị ala n'ihi na akụrụngwa na-arụ ọrụ nke ọma.

Na ahụmịhe m, uru ndị a na-agbakwunye na nchekwa ego dị oke ọnụ na nrụpụta dị elu. Enwere m ike izute oge nnyefe ma mee ka ndị ahịa m nwee obi ụtọ.

M na-etinye ego na PVC Pipe screw barrel maka extrusion n'ihi na ọ na-enye ọrụ na-adịte aka yana àgwà ọkpọkọ na-agbanwe agbanwe.

- Nhazi gbọmgbọm modular na ihe ndị dị elu na-ebelata oge nkwụsị na ụgwọ mmezi.

- Nnyocha mgbe niile na mkpuchi kwesịrị ekwesị na-enyere m aka iru ụkpụrụ ụlọ ọrụ.

| Uru | Nsonaazụ |

|---|---|

| Ogologo ogologo oge | Ọnụ ego arụmọrụ dị ala |

| Teknụzụ dị elu | Emelitere afọ ojuju ndị ahịa |

FAQ

Kedu ka m ga-esi na-edobe gbọmgbọm pipụ PVC m maka extrusion?

Ana m ehichaa gbọmgbọm ahụ mgbe niile. Ana m enyocha uwe na corrosion. Ana m edochi akụkụ ndị na-eyi ngwa ngwa. M na-eji mmanụ mmanye akwadoro na nyochaa ntọala okpomọkụ.

Ndụmọdụ: Hazie nyocha kwa ọnwa iji hụ akara mmalite nke eyi.

Kedu ọgwụgwọ elu na-arụ ọrụ kacha mma maka extrusion PVC dị elu?

Nitriding na-amasị m maka ọtụtụ ọrụ. M na-eji bimetallic ma ọ bụ tungsten carbide mkpuchi mgbe m na-edozi ogige abrasive. Ọgwụgwọ ndị a na-agbatị ndụ ọrụ ma na-eguzogide iyi.

Enwere m ike ịhazi geometry skru maka nha pipụ PVC dị iche iche?

M na-arụ ọrụ na ndị nrụpụta ka m gbanweeịghasa dayameta, pitch, na ụgbọ elu omimi. Geometry omenala na-enyere m aka inweta mgbaze kacha mma yana ịdị mma ọkpọkọ na-agbanwe agbanwe maka nha ọ bụla.

| Nhọrọ nhazi | Uru |

|---|---|

| Dayameta | Dakọtara ọkpụrụkpụ ọkpọkọ |

| Mgbapụta | Na-achịkwa usoro ihe onwunwe |

| Omimi ụgbọ elu | Na-eme ka mma ịgwakọta mma |

Oge nzipu: Ọgọst-27-2025