Mgbe m na-arụ ọrụ na Plastic Injection molding screw barrel, m na-ahụ ka imewe ya si akpụ akụkụ ọ bụla anyị na-eme. Ọmụmụ ịme anwansị na-egosi na ọbụnaobere mgbanwe na ịghasa ọsọma ọ bụ mpaghara mkpakọ nwere ike ịkwalite mma na arụmọrụ. Ma m na-eji aEjima Plastic Screw Barrelma ọ bụ gbaa aPlastic Extrusion Production Line, aka nriIgwe plastik Screw Barrelna-eme ka ihe niile dị iche.

Ọrụ nke Plastic Injection molding screw barrel

Mgbe m lere anya n'obi igwe ọ bụla na-akpụzi injection, a na m ahụ ka gbọmgbọm skru na-ebuli ihe niile dị arọ. Ọ bụghị naanị tube nwere ịghasa n'ime. Nhazi na ọrụ nke ịghasa gbọmgbọm na-akpụzi nzọụkwụ ọ bụla nke usoro ịkpụzi. Ka m kọọ isi ọrụ ya na ihe kpatara nke ọ bụla ji dị mkpa.

Na-agbaze na ngwakọta nke polymers

Ihe mbụ na-eme n'ime gbọmgbọm skru bụ agbaze na ngwakọta nke pellets plastik. M na-awụsa pellets n'ime hopper, na ịghasa na-amalite ịtụgharị n'ime gbọmgbọm ọkụ. gbọmgbọm ahụ nwere mpaghara okpomọkụ dị iche iche, ya mere rọba ahụ ji nwayọọ nwayọọ na-ekpo ọkụ. Ọtụtụ n'ime agbaze na-abịa n'ezie site na esemokwu na nrụgide nke ịghasa na-ete n'ime pellets na mgbidi gbọmgbọm. Usoro a na-eme ka plastik ghara ikpo ọkụ ma na-enyere ya aka ịgbaze nke ọma.

- gbọmgbọm mkpọsa ahụ nwere ihe nkedo helical na-atụgharị n'ime gbọmgbọm guzoro ọtọ.

- Ndị na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na gbọmgbọm tupu m amalite, ya mere polymer na-arapara ma malite ịgbaze.

- Ozugbo ịghasa ahụ na-atụgharị, ọtụtụ ike maka ịgbaze na-abịa site na shii n'etiti ịghasa na mgbidi gbọmgbọm.

- Nhazi nke ịghasa ahụ, karịsịa ka omimi ọwa na-esi esiwanye ntakịrị na ngalaba mkpakọ, na-amanye plastik na-agbaze na mgbidi gbọmgbọm dị ọkụ. Nke a na-ebuli agbaze na ịgwakọta.

- Ka plastik na-aga n'ihu, ọdọ mmiri na-agbaze na-eto ruo mgbe ihe niile gbazere. Ịkpachasị ihe na-aga n'ihu na-agwakọta plastik a wụrụ awụ ọbụna karịa.

M na-aṅa ntị mgbe niile ka plastik na-agbaze na ngwakọta. Ọ bụrụ na agbaze ahụ abụghị otu, m na-ahụ nsogbu dị ka streaks ma ọ bụ ntụpọ adịghị ike na akụkụ ikpeazụ. Nhazi gbọmgbọm ahụ, gụnyere yaogologo, pitch, na ọwa omimi, na-eme nnukwu ọdịiche na otú ọ na-esi agbaze nke ọma ma na-agwakọta ụdị plastik dị iche iche.

Ndụmọdụ:Ọtụtụ n'ime ike ịkwọ ụgbọala na gbọmgbọm mkpọsa-ihe dị ka 85-90%-na-abanye n'ime agbaze plastik, ọ bụghị naanị ịkwaga ya n'ihu.

Nbufe na homogenization

Ozugbo rọba ahụ malitere ịgbaze, gbọmgbọm screw na-arụ ọrụ ọzọ dị mkpa: ibuga ihe ahụ n'ihu na ịhụ na ọ bụ otu. Echere m na nke a dị ka mpaghara "nchịkwa njikwa" n'ime igwe. E kewara gbọmgbọm mkpọsa ahụ ụzọ atọ bụ isi, nke ọ bụla nwere ọrụ nke ya:

| Mpaghara ịghasa | Njirimara isi | Ọrụ ndị mbụ |

|---|---|---|

| Mpaghara nri | Ọwa kachasị omimi, omimi mgbe niile, ogologo 50-60%. | Na-ebufe pellets siri ike n'ime gbọmgbọm; amalite preheating site esemokwu na conduction; kọmpat ihe na-ewepụ akpa ikuku |

| Mpaghara mkpakọ | Nke nta nke nta na-ebelata omimi ọwa, 20-30% ogologo | Na-agbaze pellet plastik; compresses ihe na-abawanye nrụgide; na-ewepụ ikuku si gbazee |

| Mpaghara mita | Ọwa kacha dị omimi, omimi mgbe niile, ogologo 20-30%. | Homogenizes gbazee okpomọkụ na mejupụtara; na-ebute nrụgide maka extrusion; njikwa eruba ọnụego |

Achọpụtara m na screw barrel's geometry-dị ka pitch na omimi nke ịghasa ụgbọ elu-na-emetụta kpọmkwem otú plastic na-akpali na mix.gbọmgbọrọ agbagọ, dịka ọmụmaatụ, nyere aka mee ka nrụgide ahụ guzosie ike ma meziwanye ihe m nwere ike ịhazi, ọbụlagodi na nnukwu ọsọ. Ọ bụrụ na achọrọ m ịkwalite mmepụta ihe, enwere m ike ịbawanye skru pitch ma ọ bụ jiri oghere nri buru ibu. Ntugharị imewe ndị a niile na-enyere aka mkpọsa gbọmgbọm ahụ na-agbaze na-agbaze n'otu n'otu na ebu ahụ, nke pụtara obere ntụpọ yana akụkụ na-agbanwe agbanwe.

- njikwa okpomọkụ Barreldị oke mkpa maka agbaze otu na ịrụ ọrụ nke ọma.

- Otutu mpaghara kpo oku na-eji nwayọ na-abawanye okpomọkụ n'ebe anwụ na-ebelata ntụpọ ma melite oge okirikiri.

- Nhazi nke skru na-ebuli ngwakọta na ibuga arụmọrụ.

Ịgbanye na ebu na-ejuputa

Mgbe agbazechara rọba ahụ ma gwakọta ya, gbọmgbọm nke skru na-adị njikere maka nnukwu oge: ịgbanye plastik a wụrụ awụ n'ime ihe. Nke a bụ otu m si ahụ ka usoro a si aga:

- gbọmgbọm mkpọsa ahụ na-enweta pellet rọba raw ntụ site na hopper.

- Ihe nkedo ahụ na-atụgharị ma na-aga n'ihu n'ime gbọmgbọm ahụ a na-ekpo ọkụ, na-agbaze, na-agwakọta, ma na-eme ka plastik ahụ dị.

- Ịkpụcha ihe eji arụ ọrụ site na ịghasa na-ebute okpomoku dị nro, na-ebelata viscosity rọba ahụ ka o wee nwee ike iru.

- Ihe a wụrụ awụ na-anakọta n'ihu nke ịghasa ahụ, na-akpụ "mgbatị" nke ahụ bụ naanị ego kwesịrị ekwesị iji mejupụta ebu ahụ.

- Ihe ịghasa ahụ na-etinye ogbugba a wụrụ awụ na nnukwu nrụgide na ọsọ n'ime oghere ebu.

- Ihe nkedo ahụ na-ejigide nrụgide nkwakọ ngwaahịa iji jide n'aka na ebu ahụ jupụtara kpamkpam ma kwụọ ụgwọ maka nkwụsịtụ ọ bụla.

- Mgbe ebu ahụ mejuru, ịghasa ahụ na-eweghachite iji jikere maka okirikiri ọzọ ka akụkụ ahụ na-ajụ oyi.

M na-ekiri mgbe ọ bụla ịghasa barel na-arụ ọrụ n'oge a ogbo. Ọ bụrụ na okpomoku gbazere ma ọ bụ ọnụego eruba anaghị agbanwe agbanwe, ana m enweta ndochi ebu na-ezighi ezi ma ọ bụ ogologo oge okirikiri. Ịrụ ọrụ nke screw barel na agbaze na rọba na-akpụ akpụ na-enyere m aka ime ka oge okirikiri dị mkpụmkpụ yana ịdị mma akụkụ dị elu. Ọ bụ ya mere m ji etinye uche nke ukwuu na nhazi na ọnọdụ nke Plastic Injection molding screw barrel-ọ na-achịkwa usoro dum site na mmalite ruo n'isi.

Screw Design na mmetụta ya na nsonaazụ ịkpụzi

Dakọtara Screw Geometry na Ụdị Resin

Mgbe m họọrọ ịghasa maka igwe m, ana m eche mgbe niile maka ụdị resin m na-eme atụmatụ iji. Ọ bụghị ihe mkpuchi ọ bụla na-arụ ọrụ nke ọma na plastik ọ bụla. Ọtụtụ ụlọ ahịa na-eji kposara ebumnuche izugbe, mana ahụla m ka ndị a nwere ike ịkpata nsogbu dị ka agbaze na-enweghị isi na specks ojii na ngwaahịa ikpeazụ. Nke ahụ bụ n'ihi na ụfọdụ resin chọrọ atụmatụ ịghasa pụrụ iche iji zere ntụpọ nwụrụ anwụ ma dowe otu agbaze agbaze.

- Ihe mgbochi skru na-ekewapụ pellets siri ike na rọba a wụrụ awụ, nke na-enyere aka gbazee ngwa ngwa ma belata ojiji ike.

- Na-agwakọta ngalaba, dị ka Maddock ma ọ bụ zig-zag mixers, hụ na agbaze okpomọkụ na agba na-adị ọbụna, otú ahụ ka m na-ahụ ole na ole eruba akara na weld ahịrị.

- Ụfọdụ atụmatụ ịghasa, dị ka CRD agwakọta ịghasa, na-eji elongational eruba kama shiee. Nke a na-eme ka polymer ghara imebi ma na-enyere m aka izere gels na mgbanwe agba.

Ọmụmụ ụlọ ọrụ na-egosi na ihe ruru 80% nke igwe nwere nsogbu mmebi resin jikọtara ya na imepụta skru. M na-adakọkarị geometry skru na ụdị resin iji mee ka akụkụ m sie ike na enweghị ntụpọ.

Mmetụta na agbaze, ịgwakọta, na mmapụta

Jiometry nke skru na-akpụzi ka plastik ahụ si agbaze nke ọma, na-agwakọta, ma na-asọpụta. Achọpụtara m na atụmatụ ịghasa dị elu, dị ka ụgbọ elu mgbochi na ngalaba agwakọta, na-akwanye polymer agbazeghị nso na mgbidi gbọmgbọm ahụ. Nke a na-akwalite ikpo ọkụ ọkụ ma na-enyere mgbaze ahụ aka ịghọ otu.

Nke a bụ nlele ngwa ngwa ka ụdị screw geometry dị iche iche si arụ ọrụ:

| Ụdị geometry ịghasa | Ịgbaze arụmọrụ | Ịgwakọta Ịrụ Ọrụ | Ogo mmepụta |

|---|---|---|---|

| Ihe mgbochi ịghasa | Elu | Na-agafeghị oke | Ọ dị mma, ma ọ bụrụ na ntinye aka kacha mma |

| Mkpọsa akụkụ atọ | Na-agafeghị oke | Elu | Ọ dị mma na ngwakọta kwesịrị ekwesị |

| Maddock Mixer | Na-agafeghị oke | Elu | Kacha mma maka agba na ọnọdụ okpomọkụ |

M na-achọ mgbe niile maka nguzozi. Ọ bụrụ na m na-akwali maka mmepụta dị elu, enwere m ike ịla n'iyi. Nkenri ịghasa imewen'ime ihe m na-akpụzi screw barrel nke plastik na-enyere m aka ịnọgide na-agbaze okpomọkụ, belata ntụpọ, ma na-ebuga akụkụ na-agbanwe agbanwe oge ọ bụla.

NDỤMỌDỤ: M na-enyocha ogo agbaze site n'ile anya ngbanwe agba na ike akụkụ. Ihe nkedo a haziri nke ọma na-eme ka nke a dị mfe.

Nhọrọ ihe maka Plastic injection molding screw barrel

Nguzogide iyi na corrosion

Mgbe m na-ahọrọ ihe maka aPlastic injection molding skru barrel, M na-eche mgbe niile banyere otú ọrụ ahụ siri sie ike. Ụfọdụ plastik nwere eriri iko ma ọ bụ mineral ndị na-eme dị ka akwụkwọ aja, na-eyi skru na gbọmgbọm ngwa ngwa. Ndị ọzọ, dị ka PVC ma ọ bụ resins na-ere ọkụ, nwere ike na-emebi emebi. Achọrọ m ka akụrụngwa m dịgide, yabụ m na-achọ ihe na-emegide ma iyi na corrosion.

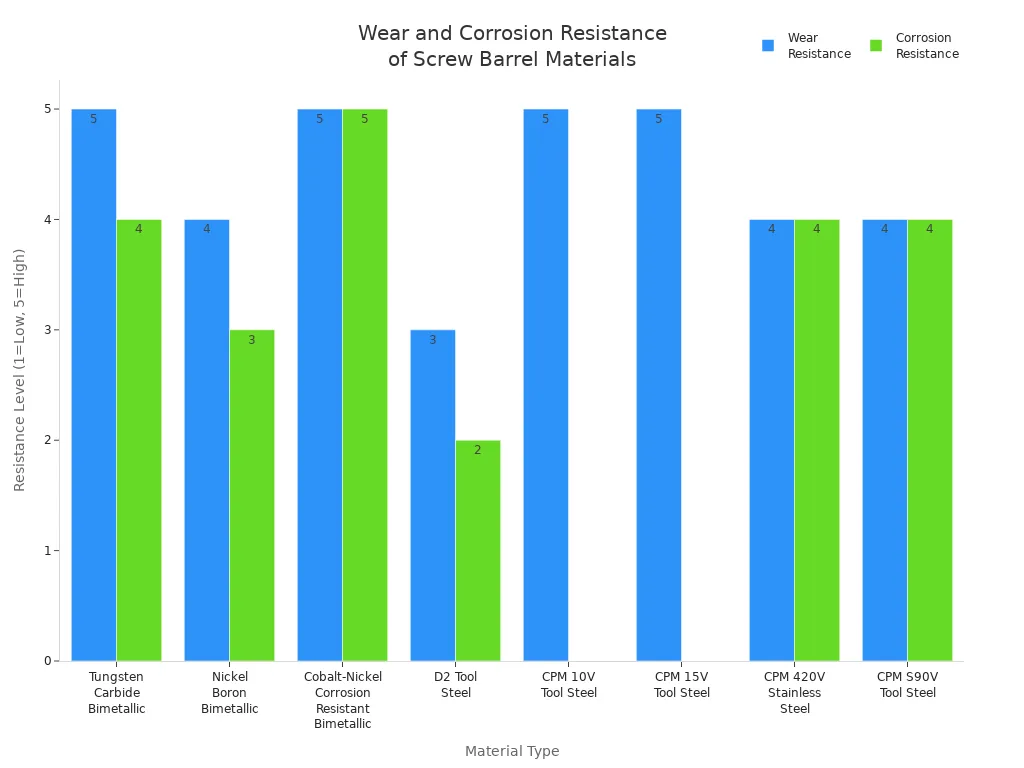

Nke a bụ nlele ọsọ ọsọ na nhọrọ ụfọdụ a na-ahụkarị:

| Ụdị ihe | Yiri Nguzogide | Nguzogide corrosion | Akpa eji eme ihe kacha mma |

|---|---|---|---|

| Nitrided ígwè | Ọ dị mma | Ogbenye | Ejupụtaghị, resins anaghị emebi emebi |

| Bimetallic Barrel | Magburu onwe | Ọ dị mma / mara mma | Ihe jupụtara, ihe na-emebi emebi, ma ọ bụ ihe na-emebi emebi |

| Ngwá Ọrụ Steel (D2, usoro CPM) | Elu | Ọ dị oke oke/Elu | Ihe mgbakwunye iko / mineral jupụtara ma ọ bụ ihe siri ike |

| Barrel Ekpuchiri Ọpụrụiche | Dị Elu | Elu | Oke oke iyi/corrosion, resins ike ike |

Ahụla m na iji bimetallic barel ma ọ bụ nchara ngwá ọrụ nwere ike ịgbatị ndụ akụrụngwa m. Ihe ndị a na-eguzogide ma ncha na kemịkal ọgụ. Mgbe m na-eji ngwakọta ziri ezi, m na-etinye obere oge na nrụzi na ọtụtụ oge na-eme akụkụ dị mma.

NDỤMỌDỤ: Ọ bụrụ na m na-edozi ọtụtụ plastik jupụtara na iko ma ọ bụ ọkụ na-ere ọkụ, m na-ahọrọ mgbe ọ bụla gbọmgbọm nwere mkpuchi dị elu ma ọ bụ bimetallic liners. Nke a na-eme ka usoro mmezi m bụrụ amụma amụma yana oge ọdịda m dị ala.

Ịhọrọ ihe maka polymers akọwapụtara na ihe mgbakwunye

Plastic ọ bụla nwere àgwà nke ya. Ụfọdụ na-adị nwayọọ, ebe ndị ọzọ na-arụ ọrụ ike. Mgbe m na-ahọrọ ihe maka ịghasa na gbọmgbọm, m na-ejikọta ha na plastik na ihe mgbakwunye m na-eji ọtụtụ.

- Nri iko na mineral na-ata ọla dị nro, yabụ m na-aga maka mkpuchi alloys siri ike ma ọ bụ mkpuchi carbide tungsten.

- Plastics na-emebi emebi, dị ka PVC ma ọ bụ fluoropolymers, chọrọ gbọmgbọm sitere na alloys dabere na nickel ma ọ bụ igwe anaghị agba nchara.

- Akwa-okpomọkụ resins nwere ike ime ka thermal ike ọgwụgwụ, otú ahụ ka m na-elele naịghasa na gbọmgbọmgbasaa n'otu ọnụego ahụ.

- Ọ bụrụ na m na-eji ọtụtụ ihe dị iche iche, mgbe ụfọdụ ana m ahọrọ ụdị ịghasa modular. N'ụzọ dị otú ahụ, enwere m ike ịgbanwe akụkụ ndị na-eyi akwa na-enweghị dochie ihe nkedo dum.

M na-agwa onye na-eweta resin m okwu mgbe niile maka ndụmọdụ. Ha maara ihe ndị na-arụ ọrụ kacha mma na plastik ha. Site n'ịhọrọ ihe ndị dị mma, ana m edobe screw barrel m na-eji plastik injection na-agba ọsọ nke ọma ma na-ezere ndakpọ ihe ijuanya.

Ihe ohuru ohuru na Teknụzụ Injection Plastic Molding screw barrel Technology

Ihe mkpuchi dị elu na ọgwụgwọ elu

Ahụla m ka mkpuchi dị elu na ọgwụgwọ elu nwere ike isi mee nnukwu mgbanwe n'ogologo ogologo mgbịrịgba mkpọsa na-adịru. Mgbe m na-eji gbọmgbọm nwere lining bimetallic ma ọ bụ mkpuchi carbide tungsten, ana m achọpụta obere iyi na mmebi dị ntakịrị. Ihe mkpuchi ndị a na-enyere gbọmgbọm aka iguzogide abrasion na corrosion, ọbụna mgbe m na-agba ọsọ ihe siri ike dị ka resins jupụtara iko. Ụfọdụ mkpuchi na-eji nano-materials, nke na-enyere aka na ikpo ọkụ ọkụ ma mee ka usoro ahụ guzosie ike. Ọ na-amasịkwa m na ọgwụgwọ ndị a na-ebelata kọntaktị metal na metal, nke mere na ịghasa na gbọmgbọm adịghị egweri ibe ha ngwa ngwa.

Nke a bụ ihe m na-achọ na mkpuchi dị elu:

- Alloys na-eguzogide iyi nke dabara na ihe m na-ahazi

- Ọgwụgwọ dị n'elu nke na-ejikwa oke okpomọkụ na kemịkalụ ike ike

- Ihe mkpuchi na-eme ka usoro ahụ guzosie ike ma belata oge nkwụsị

Mgbe m na-ahọrọ mkpuchi kwesịrị ekwesị, m na-etinye obere oge na nhazi na oge na-eme ka akụkụ dị mma. Ọkachamara metallurgical dị mkpa ebe a. Ngwakọta kwesịrị ekwesị nke alloy na mkpuchi nwere ike okpukpu abụọ ma ọ bụ ọbụna okpukpu atọ ndụ ọrụ nke akụrụngwa m.

Nhazi omenala maka ngwa pụrụ iche

Mgbe ụfọdụ, achọrọ m ihe karịrị naanị ọkọlọtọ skru barrel. Nhazi omenala na-enyere m aka idozi ihe ịma aka ịkpụzi pụrụ iche. Dịka ọmụmaatụ, ejirila m conical ejima skru barrel kwalite ngwakọta na njikwa okpomọkụ. Ahụla m skru omenala emebere iji mee ka oge okirikiri dị ngwa, melite ogo agbaze, ma belata ịkpacha ajị anụ.

Ụfọdụ nhọrọ m na-atụle maka atụmatụ omenala:

- Skru na orù emere site na nchara pụrụ iche dị ka D2 Tool Steel ma ọ bụ akara CPM

- Ihe siri ike dị n'elu dị ka Stelite ma ọ bụ Colmonoy maka ogologo ogologo oge

- Ihe mkpuchi gbọmgbọm ahaziri maka ihe ndị akọwapụtara, dị ka ntọala nickel nwere carbide maka polymer nwere iko

- Mgbakọ valvụ omenala na mkpuchi njedebe nwere mkpuchi dị elu

Ngwọta omenala na-ekwe ka m kwekọọ na akụrụngwa m na mkpa nke usoro m. Nke a pụtara ogo akụkụ ka mma, okirikiri ọsọ ọsọ, yana obere oge ọdịda. M na-arụ ọrụ mgbe niile na otu ndị na-emepụta ihe na-aghọta ngwa m ma nwee ike ịnapụta nka dị elu.

Ịmata na Nchọpụta nsogbu Screw Barrel

Ihe ịrịba ama a na-ahụkarị nke eyi ma ọ bụ ọdịda

Mgbe m na-agba igwe m, ana m ele anya mgbe niile maka akara ịdọ aka na ntị n'oge na ihe adịghị mma na gbọmgbọm screw. Ịchọpụta nsogbu ndị a n'oge na-enyere m aka izere nsogbu ndị ka ukwuu ma emechaa. Nke a bụ ụfọdụ ihe m na-ele anya:

- Ihe na-agbapụta gburugburu gbọmgbọm ahụ, nke na-apụtakarị n'akara aka ma ọ bụ nke ukwuu.

- Akụkụ ndị na-apụta na nha na-ekwekọghị ekwekọ ma ọ bụ spek ojii — ndị a na-arụtụ aka na ngwakọta na-adịghị mma ma ọ bụ mmetọ.

- Okpomọkụ na-arụ ọrụ dị elu, mgbe ụfọdụ n'ihi esemokwu ma ọ bụ mpụta carbon n'ime gbọmgbọm.

- Mkpọtụ ma ọ bụ ịma jijiji dị iche iche n'oge arụ ọrụ. Ndị a nwere ike ịpụta ngbanwe, agbaji agbaji, ma ọ bụ ọbụna ihe mba ọzọ dị n'ime.

- Nrụgide nrụgide ma ọ bụ na-agbaze na-adịghị mma, nke na-eme ka ọ sie ike imeju ihe nke ọma.

- Mgbochi ma ọ bụ ihe na-ewuli elu n'ime gbọmgbọm ahụ, na-eduga n'oge nkwụsị na akụkụ ọjọọ.

- Nsogbu agwakọta agba ma ọ bụ mmetọ, na-esitekarị na ihe fọdụrụ ma ọ bụ njikwa okpomọkụ na-adịghị mma.

- Nrụrụ na-ahụ anya ma ọ bụ pitting, karịsịa ma ọ bụrụ na m na-agba ọsọ resins corrosive.

- Ụgbọ elu nke skru ma ọ bụ mkpuchi gbọmgbọm, nke m na-ahụkarị mgbe m na-eji ihe nchacha abrasive dị ka eriri iko.

- Na-agbaze nwayọ nwayọ, ihe mkpofu karịa, yana ogologo oge okirikirika akụrụngwa na-agwụ ike.

Ọ bụrụ na m achọpụta nke ọ bụla n'ime ihe ịrịba ama ndị a, amaara m na ọ bụ oge ịlele screw barrel tupu ihe aka njọ.

Ndụmọdụ maka nchọpụta nsogbu na nlekọta bara uru

Iji mee ka igwe m na-arụ ọrụ nke ọma, ana m agbaso usoro nhazi oge niile. Nke a bụ ihe na-abara m uru:

- M na-eji naanị mmanu mmanu nke onye nrụpụta tụrụ aro.

- Ana m elele ọkwa mmanụ hydraulic kwa ụbọchị ma dochie mmanụ na nhazi oge.

- M na-ekiri okpomọkụ mmanụ ma ghara ikwe ka ọ kpoo oke ọkụ.

- Ana m enyocha hoses, nfuli, na valvụ maka ntapu ma ọ bụ eyi.

- Ana m ehicha ma na-akpachikwa eriri igwe kpo oku kwa ọnwa.

- Ana m eji foto thermal hụ nsogbu kpo oku n'oge.

- Ana m enyocha oge okirikiri, ọnụego mkpọpu, na ojiji ike iji jide okwu tupu ha etoo.

- M na-ehicha skru na gbọmgbọm ahụ mgbe niile ka m ghara ịmalite.

- Ana m ejide n'aka na ịghasa ahụ kwụ ọtọ ma kwekọọ n'oge echichi.

- Ana m azụ ndị otu m ka ha hụ akara mmalite nke eyi ma mee ka ọnọdụ nhazi kwụ ọtọ.

Ịnọgide n'elu ọrụ ndị a na-enyere m aka izere ndakpọ na-eme ka ahịrị mmepụta m rụọ ọrụ nke ọma.

Mgbe m lekwasịrị anya na sayensị dị n'azụ Plastic Injection molding screw barrel, m na-ahụ ezigbo nsonaazụ. Ana m enweta akụkụ ka mma, okirikiri ọsọ ọsọ, yana obere oge nkwụsị.

- Ọnụ ego mmezi dị ala

- Ogo ngwaahịa emelitere

- Ogologo akụrụngwa ndụ

Ịnọgidesi ike na sayensị screw barrel na-eme ka nrụpụta m bụrụ nke a pụrụ ịdabere na ya na nke ọma.

FAQ

Kedu akara na-agwa m gbọmgbọm skru m chọrọ nnọchi?

A na m achọpụta obere specks ojii, akụkụ na-adaghị adaba, ma ọ bụ mkpọtụ dị iche iche. Ọ bụrụ na m ahụ ihe ndị a, m na-elele gbọmgbọm skru maka eyi ma ọ bụ mebie ozugbo.

Ugboro ole ka m ga-ehicha skru barrel m?

Ana m ehichaa gbọmgbọm skru m mgbe mgbanwechara ihe ọ bụla. Maka ịgba ọsọ mgbe niile, ana m elele ma hichaa ya ọbụlagodi otu ugboro n'izu iji gbochie nrụpụta.

Enwere m ike iji otu gbọmgbọm skru maka ụdị plastik niile?

- Ana m ezere iji otu gbọmgbọm skru maka rọba ọ bụla.

- Ụfọdụ plastik chọrọ ihe pụrụ iche ma ọ bụ mkpuchi iji gbochie iyi ma ọ bụ mmebi.

Oge nzipu: Ọgọst-20-2025