The plastic injection molding screw barrel na-eguzo na obi nke usoro ịkpụzi ọ bụla. Mgbe ha na-ahọrọ ihe dị eluIgwe plastik Screw Barrelma ọ bụ aPlastic ejima ịghasa Extruder Barrel, ndị na-emepụta ihe na-ahụ ka ọ na-erugharị ihe dị nro, ntụpọ ole na ole, na ọnụ ala dị ala.Igwe anaghị agba nchara ejima screw Extruder Barrelnhọrọ na-enyekwara aka ịgbatị ndụ akụrụngwa na igbutu oge.

Ọrụ ndị dị mkpa nke ịgbanye plastik na-akpụzi screw Barrel

Ngwa plastik na-agbaze na imekọ ihe

The plastic injection molding screw barrel na-ekere òkè dị ukwuu n'ịgbanwe pellets plastik siri ike ka ọ bụrụ ihe na-adịghị mma, gbazere. N'ime gbọmgbọm ahụ, ịghasa na-atụgharị ma na-ebugharị pellets n'ihu. Ka pellets na-aga, esemokwu na igwe ọkụ na-agbaze ha. gbọmgbọm ahụ na-edobe okpomọkụ ọbụna, ya mere plastik na-agbaze n'ogo kwesịrị ekwesị. Usoro a na-enyere aka izere lumps ma ọ bụ ntụpọ oyi na ihe.

Ndụmọdụ: gbọmgbọm screw nwere mpaghara atọ bụ isi - nri, mkpakọ, na mita. Mpaghara ọ bụla nwere ọrụ pụrụ iche. Mpaghara ndepụta na-akpali ma na-ekpo ọkụ nke pellets. Mpaghara mkpakọ na-agbaze plastik ma wepụ ikuku. Mpaghara metering na-eme ka agbaze ahụ dị nro ma dị njikere maka ịgba ogwu.

| Mpaghara | Ọrụ ndị mbụ |

|---|---|

| Mpaghara nri | Na-ebufe pellets, na-ekpo ọkụ ha, na kọmpat iji wepụ akpa ikuku. |

| Mpaghara mkpakọ | Na-agbaze plastik ma wepụ ikuku site na nrụgide na ịkwa akwa. |

| Mpaghara mita | Homogenizes gbazee, na-ewuli nrụgide, na-edozi eruba maka injection. |

Njikwa okpomọkụ dị mkpa nke ukwuu. Dịka ọmụmaatụ, UPVC siri ike chọrọ kpo oku nke ọma n'etiti 180-190 Celsius. gbọmgbọm screw na-eji ma igwe ọkụ dị n'èzí yana mmegharị nke screw iji mepụta oke okpomọkụ. Ntụle a na-eme ka plastik ghara ire ọkụ ma ọ bụ ịrapara. Ọsọ nke ịghasa na-emetụtakwa ka plastik si agbaze nke ọma. Ọ bụrụ na ịghasa ejiri nwayọọ nwayọọ tụgharịa, agbaze ahụ nwere ike ghara ịdị ọkụ nke ukwuu. Ọ bụrụ na ọ tụgharịrị ngwa ngwa, rọba ahụ nwere ike ikpo ọkụ. The plastic injection molding screw barrel na-eme ka agbaze ya dị mma maka ogbugba ọ bụla.

Ịgwakọta ihe mgbakwunye na ịgba mbọ hụ na agba ọ bụla

Ndị na-emepụta ihe na-agbakwụnyekarị agba agba ma ọ bụ ihe mgbakwunye pụrụ iche na plastik. The plastic injection molding screw barrel na-agwakọta ihe ndị a n'ime agbaze. Nhazi nke skru, nwere ngalaba ngwakọta pụrụ iche, na-enyere aka ịgwakọta ihe niile n'otu n'otu. Ngwakọta a na-akwụsị streaks ma ọ bụ ntụpọ ịpụta na ngwaahịa ikpeazụ.

Ịgbanwe agba nwere ike ịdị aghụghọ. Mgbe ụfọdụ,pigmenti akọrọ na-arapara n'ime hopper ma ọ bụ ghara ịgwakọta nke ọma. Iru mmiri nwere ike imebi na resin na àgwà pigmenti. Kpọmkwem dose nke colorants dị mkpa. Igwe na-eji gravimetric blender tụọ ego kwesịrị ekwesị. Nhazi ebu na-enyekwa aka idobe agba ọbụna gafee akụkụ dị iche iche.

Mara: Eserese ịghasa dị elu, dị ka ihe mgbochi ma ọ bụ skru Maddock, na-agbaji lumps wee gbasaa agba nke ọma. Ndị a aghụghọ nwere ikena-ebuli arụmọrụ ịgwakọta ihe karịrị 20% wee belata ọnụ ahịa mkpofu ihe ruru 30%. Nchacha na nhazi oge niile na-eme ka gbọmgbọm skru na-arụ ọrụ kacha mma, yabụ na agba na-abụ eziokwu site na ogbe ruo na batch.

Na-ebufe na ịgbanye plastik a wụrụ awụ

Ozugbo rọba ahụ gbazere wee gwakọta ya, gbọmgbọm mkpọsa ahụ na-ebuga ihe a wụrụ awụ n'ebe ebu. Ihe nkedo ahụ na-atụgharị n'ime gbọmgbọm ahụ na-ekpo ọkụ, na-eme ka agbaze ahụ gaa n'ihu. Mgbe ihe zuru ezu na-ewuli elu, ịghasa na-eme ihe dị ka plunger. Ọ na-agbanye rọba a wụrụ awụ n'ime ihe ebu na nnukwu nrụgide.

Nke a bụ ka usoro a si arụ ọrụ:

- Pellets plastik na-abanye na ngalaba ndepụta ma gaa n'ihu ka ịghasa na-atụgharị.

- Esemokwu na okpomọkụ gbazee pellets.

- Ihe nkedo ahụ na-agbanye mgbaze ahụ, na-eme ka ọ dị nro na ọbụna.

- Ihe ịghasa ahụ na-aga n'ihu wee tinye rọba a wụrụ awụ n'ime ihe.

Nkeplastic injection ịkpụzi ịghasa gbọmgbọmna-eme ka ihe niile na-aga nke ọma. Ọ na-achịkwa nrụgide na mgbaba, ya mere ogbunigwe ọ bụla na-ejupụta ebu ahụ nke ọma. Ihe siri ike nke gbọmgbọm na-eguzo ọtọ na-eyi ma na-adọka, na-eme ka usoro ahụ bụrụ nke a pụrụ ịdabere na ya ka oge na-aga.

Na-eme ka arụ ọrụ dị mma site n'iji mgbanye plastik ziri ezi na-akpụzi screw Barrel

Mmetụta nke Screw Geometry na Barrel Design

Ịghasa geometryna-akpụzi ka plastik si agbaze ma na-agwakọta n'ime gbọmgbọm ahụ. Ogologo, udi eri, pitch, na ọsọ nke ịghasa niile na-ekere òkè. Mgbe ndị injinia na-agbanwe ihe ndị a, ha nwere ike ijikwa oke okpomọkụ na ịkwa akwa plastik na-enweta. Nke a na-enyere aka ịmepụta otu agbaze ma na-ebelata ntụpọ dị ka streaks ma ọ bụ afụ.

Oke mkpakọ, nke tụlere omimi nke nri nke skru na mpaghara metering, na-emetụta etu esi achịkọba rọba ahụ nke ọma. Oke dị elu na-abawanye njupụta na ngwakọta mana ọ nwere ike ọ gaghị adabara plastik nwere mmetụta okpomọkụ. Nrụgide azụ dịkwa mkpa. Ọ na-akwali resin a wụrụ awụ nke ukwuu, na-agbaji ibe n'agbazeghị ma na-emeziwanye ngwakọta. Agbanyeghị, oke nrụgide azụ nwere ike imebi ihe ndị siri ike.

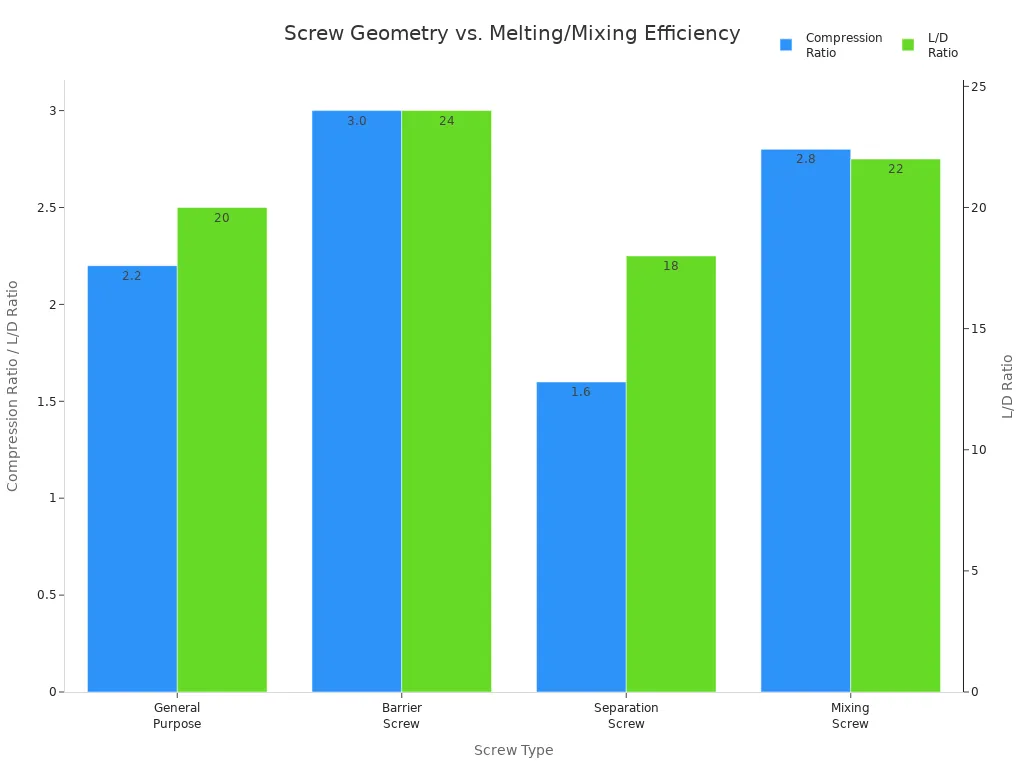

Nke a bụ tebụl na-egosi otú ụdị screw dị iche iche na geometry ha si emetụta nrịda na nhịahụ nke ọma:

| Ụdị ịghasa | Ngwa ndị dabara adaba | Oke mkpakọ | Oke L/D | Ojiji a na-ahụkarị | Mmetụta na mgbaze na ngwakọta arụmọrụ |

|---|---|---|---|---|---|

| Ebumnuche izugbe | ABS, PP, PE | 2.2:1 | 20:1 | Ụlọ Ngwa | Na-agbaze ma na-agwakọta ya na shear na-agafeghị oke na otu. |

| Ihe mgbochi ịghasa | PA + GF, PC | 3.0:1 | 24:1 | Akụkụ ihe owuwu | Akwa shiee na ịgwakọta, mma agbaze homogeneity na ngwaahịa àgwà. |

| Nkewa nkewa | PVC, POM | 1.6:1 | 18:1 | Ọkụ, Ngwa | Na-achịkwa ịkwa akwa, na-ebelata mmebi, na-eme ka agbaze na-agbanwe agbanwe. |

| Ngwakọta ịghasa | PMMA, PC+GF | 2.8:1 | 22:1 | Mkpuchi ọkụ | Ngwakọta agbakwunyere, agbaze otu, akụrụngwa anya emelitere. |

Ndị injinia na-ejikarị chaatị atụnyere screw geometry. Chaatị dị n'okpuru na-egosi otú mkpakọ mkpakọ na L/D ruru si dị iche maka ụdị ịghasa dị iche iche:

Igwe mmiri dị n'ime plastik emebere nke ọma nwere jiometrị ziri ezi na-eme ka plasticization kwụsie ike, okpomọkụ gbazee na-agbanwe agbanwe, yana ihe na-aga nke ọma. Nke a na-eduga na gloss elu ka mma, ntụpọ ole na ole, na akụkụ ndị a kpụrụ akpụ siri ike karị.

Nhọrọ ihe maka ịdịte aka na nguzogide iyi

Ịhọrọ ihe ndị kwesịrị ekwesị maka gbọmgbọm screw na-eme nnukwu ọdịiche na ogologo oge ọ na-adị na otú ọ na-arụ ọrụ nke ọma. Ndị na-emepụta ihe na-eji ígwè siri ike na mkpuchi dị elu alụso iyi na corrosion ọgụ. Dịka ọmụmaatụ, 38CrMoAlA nitrided steel na-arụ ọrụ nke ọma maka ọrụ ọkọlọtọ, ebe SKD61 (H13) igwe igwe na-ejikwa resins injinịa siri ike. Ogwe Bimetallic nwere tungsten carbide ma ọ bụ alloys dabere na nickel na-enye nguzogide kachasị elu na abrasion na kemịkalụ.

| Ụdị ihe | Yiri Nguzogide | Nguzogide corrosion | Isi ike nkịtị | Isi ngwa ngwa |

|---|---|---|---|---|

| 38CrMoAlA Nitrided Steel | ★ ★ ★☆☆ | ★ ★☆☆☆ | ~ 1000 HV (Nitrided) | Kwesịrị ntụkwasị obi maka ngwa ọkọlọtọ |

| Ngwa igwe SKD61 (H13). | ★ ★ ★ ★☆ | ★ ★ ★☆☆ | 48–52 HRC | Resins injinia siri ike, nrụgide thermal |

| Bimetallic Barrel | ★ ★ ★ ★ ★ | ★ ★ ★ ★☆ | 60–68 HRC | Abrasive, fiberglass, ire ọkụ na-egbochi, rọba arụgharịrị arụgharị |

Nhọrọ ndị ọzọ na-ewu ewu gụnyere AISI 4140 na 4340 alloy steels maka ojiji n'ozuzu, D2 na CPM ígwè ígwè maka plastik abrasive, na Hastelloy ma ọ bụ Inconel maka gburugburu ndị na-emebi emebi. Ọgwụgwọ dị n'elu dị ka nitriding na chromium plating na-akwalite ike na ogologo ndụ. Mgbe ndị na-emepụta ihe na-ahọrọ ihe kwesịrị ekwesị, ha na-ebelata oge nkwụsịtụ na ụgwọ ọrụ, na-eme ka mmepụta na-arụ ọrụ nke ọma.

NDỤMỌDỤ: Ogwe Bimetallic nwere ọdịnaya tungsten carbide dị elu na-adịte aka karịa, ọkachasị mgbe a na-edozi abrasive ma ọ bụ polymer jupụtara.

Dakọtara Screw Barrel na Plastics dị iche iche

Ọ bụghị plastik niile na-akpa àgwà otu ụzọ n'oge ịkpụzi. Ụdị nke ọ bụla chọrọ nhazi gbọmgbọm a kapịrị ọnụ iji nweta nsonaazụ kacha mma. Ndị injinia na-elele okpomoku plastik na-agbaze, viscosity na nkwụsi ike. Ha dabara na geometry skru, omimi oghere na mkpuchi gbọmgbọm dabara na mkpa ihe ahụ.

Dịka ọmụmaatụ, polycarbonate (PC) chọrọ ịghasa ogologo ya na ntinye nwayọọ nwayọọ na ngalaba ngwakọta iji gbochie mmebi. Naịlọn (PA) chọrọ skru mutant nwere oke mkpakọ dị elu yana obere oghere n'etiti ịghasa na gbọmgbọm iji jikwaa shii. PVC na-achọ gbọmgbọm na-eguzogide corrosion na skru dị ala iji zere ikpo oke ọkụ na imepụta ihe.

| Ụdị plastik | Nkịtị imewe nkesa | Mmetụta na Ogo |

|---|---|---|

| Polycarbonate (PC) | Nnukwu L / D ruru (~ 26), ịghasa nwayọ nwayọ, oke mkpakọ ~ 2.6, ngalaba agwakọta | Ezi plasticizing, na-egbochi mmebi, na-eme ka homogeneity dịkwuo mma |

| Naịlọn (PA) | Mutant ịghasa, L/D 18-20, mkpakọ ruru 3-3.5, obere oghere | Na-egbochi ikpo oke ọkụ, na-achịkwa ịkwa akwa, na-akwado ogo agbaze |

| PMMA | Nke nta nke nta ịghasa, L/D 20-22, mkpakọ ruru 2.3-2.6, agwakọta mgbanaka | Ịgbaze nke ọma, na-egbochi nsogbu mmiri, na-edobe nkenke |

| PET | L / D ~ 20, obere shiee ịghasa, mkpakọ ruru 1.8-2, ọ dịghị agwakọta mpaghara | Na-egbochi ikpo oke ọkụ, na-achịkwa ịkwa akwa, dabara maka ihe eji emegharịgharị |

| PVC | Skru dị ala, gbọmgbọm na-eguzogide corrosion, L/D 16-20, enweghị mgbanaka nlele | Na-egbochi ikpo oke ọkụ na corrosion, njikwa okpomọkụ kwụsiri ike |

Ikwekọ n'ime akpa rọba na-akpụzi skru barrel na ụdị rọba ahụ na-enyere aka izere ntụpọ dị ka agbaze agbaze, agbaze na-ezughị ezu, ma ọ bụ mgbagha. Ọ na-emekwa ka oge okirikiri na arụmọrụ ike dịkwuo mma.

Mara: Ịkwalite gbọmgbọm skru maka rọba dị iche iche nwere ike ịkwalite mmepụta ihe ruru 25% ma belata ntụpọ, na-echekwa oge na ego.

Ndụmọdụ nlekọta maka ogologo ndụ na ntụkwasị obi

Nlekọta anya mgbe niile na-eme ka gbọmgbọm skru na-arụ ọrụ kacha mma. Ndị na-arụ ọrụ kwesịrị inyocha gbọmgbọm maka uwe, ncha, ma ọ bụ pitting mgbe ọ bụla ewepụrụ ihe nkedo ahụ. Iji ogige nchacha nke azụmahịa na-ehicha ihe na-ewepụ ihe fọdụrụnụ ma gbochie nrụpụta carbon. Nleba anya nrụgide, okpomọkụ, na ịghasa ọsọ na-enyere aka ịhụ nsogbu n'oge.

Nke a bụ ndụmọdụ ụfọdụ bara uru:

- Lelee gbọmgbọm mkpọsa n'anya yana jiri nlele oge ọ bụla ewepụrụ ihe nkedo ahụ.

- Na-asachapụ gbọmgbọm ahụ kwa izu maka ịgba ọsọ na-aga n'ihu, ma ọ bụ ụbọchị 2-3 ọ bụla ma ọ bụrụ na ị na-agbanwe plastik mgbe niile.

- Richaa akụkụ ndị na-akpụ akpụ kwa ụbọchị ma were mmanu dị elu tee ha kwa izu.

- Jiri akụrụngwa dị ọcha wee chekwaa ya nke ọma ka ịzere mmetọ.

- Zụọnụ ndị na-arụ ọrụ ụgbọ oloko ka ha mata akara iyi na idobe ndekọ nlekọta zuru ezu.

- Chekwaa akụkụ mapụtara iji wedata oge ezumike.

- Mgbe emechiri ya, mee ihe nkedo ahụ na obere ọsọ iji kesaa plastik fọdụrụnụ, jiri ihe ncha pụrụ iche mee ka ọ dị ọcha ma tinye mmanụ nchebe.

Kpọọ: Ogwe bimetallic nwere ihe mkpuchi ígwè nwere ike ịdịru okpukpu atọ karịa skru ọkọlọtọ.Ndozi kwesịrị ekwesị na lubricationgbatịa ndụ ma belata oge mmezi.

Igwe ihe mkpuchi mkpuchi mkpuchi rọba nke edobere nke ọma na-ebuga ịdị mma na-agbanwe agbanwe, na-ebelata obere oge, ma na-akwado mmepụta nke ọma.

The Plastic Injection molding screw barrel na-arụ ọrụ dị mkpa n'iwepụta ogo ngwaahịa na-agbanwe agbanwe yana mmepụta nke ọma.

- Orù mkpọsa dị elu na-eme ka ịgbaze agbaze, belata ihe mkpofu, na ịkwalite arụmọrụ.

- Nlekọta anya mgbe niile na-egbochi oge nkwụsịtụ ma gbasaa ndụ akụrụngwa.

- Ihe nchekwa ihe na ike na-agbakwụnye ngwa ngwa.

- Mgbanwe ngwa ngwa na-abawanye ikike na uru.

FAQ

Kedu akara na-egosi gbọmgbọm skru chọrọ nnọchi?

Ndị na-arụ ọrụ na-achọpụta agbaze na-ezighi ezi, ntụpọ na-abawanye, ma ọ bụ obere okirikiri. Ha na-ahụkwa uwe a na-ahụ anya, ncha, ma ọ bụ olulu n'ime gbọmgbọm ahụ.

Ugboro ole ka mmadụ kwesịrị ịsacha gbọmgbọm mkpọsa?

Ọtụtụ ndị na-emepụta ihe na-ehicha barel ahụ kwa izu. Ọ bụrụ na ha na-agbanwekarị plastik, ha na-ehicha ya kwa ụbọchị abụọ ruo atọ.

Otu gbọmgbọm ịsa ahụ nwere ike ịrụ ọrụ maka plastik niile?

Ee e, ụdị rọba ọ bụla chọrọ nhazi gbọmgbọm nke ịghasa. Iji egwuregwu kwesịrị ekwesị na-eme ka mma ngwaahịa na-ebelata ihe mkpofu.

Oge nzipu: Ọgọst-15-2025